Both shop drawings and design drawings are integral to the design and fabrication of a variety of projects, from piping and platework, through to bridge, commercial and industrial developments. Though often confused as the same thing, structural steel shop drawings and design drawings each play a distinctly different, but equally important, role in the construction process.

Design drawings are used in the early stage of design development as a means to communicate design ideas and proposals. In comparison, shop drawings provide the details needed by a fabricator during fabrication, assembly, installation and erection, such as the specified material, weld types and connections.

What are Design Drawings?

Design drawings are undertaken as the first step of the design phase. They are usually aesthetic concepts or renderings that represent a client’s ideas and designers’ intent.

A number of different practitioners may be involved in the preparation of design drawings, including architects, engineers, contractors and suppliers. They allow the architect or designer to communicate their concepts and vision to contractors, builders and fabricators.

Design drawings generally include the following information:

- Interior and exterior elevations

- Interior and exterior 3D renderings

- Floor plans

- Site plans

- Design layout

- Aesthetic elements, such as colors, textures and some materials

- Connection design

What are Shop Drawings?

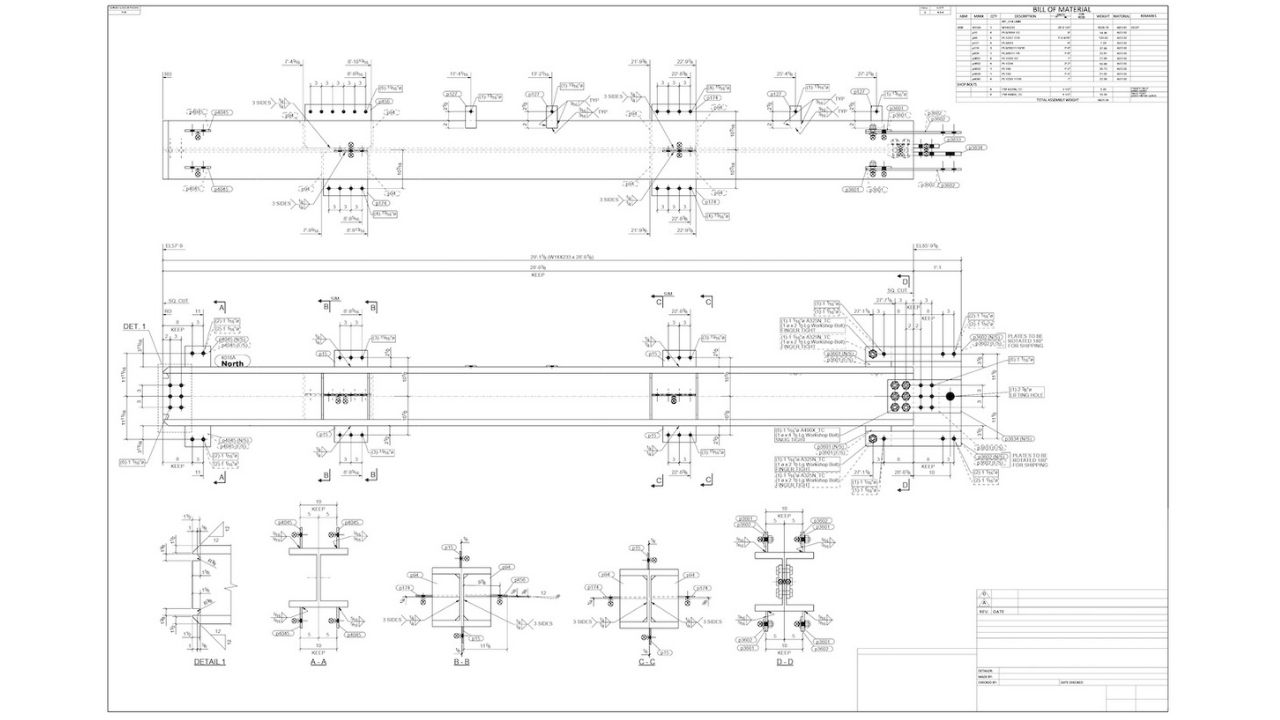

Shop drawings (also known as fabrication drawings) are detailed plans that translate design intent. They provide fabricators with the information necessary to manufacture, fabricate, assemble and install all the components of a structure. This includes materials and dimensions required, as well as explanations for assembly, installation and erection.

In general, engineers, steel detailers, steel modelers and fabricators are responsible for creating shop drawings. They generally include the following information:

- Information required for fabrication, such as dimensions and special instructions including connection details

- Applicable fabrication standards

- Installation and erection information

- Dimensions that require on-site verification

- Comparisons to the construction documents to enable approval by the architect or engineer

- Notes on changes from the construction documents to enable approval by the architect or engineer.

Why Shop Drawings are Important

Precise, accurate structural steel fabrication drawings are essential and can help:

- Ensure clear communication between the architect or designer, the client, and the fabricator.

- Ensure that the fabrication process flows seamlessly, as there is no need to halt fabrication to confirm missing details or dimensions. In this way, shop drawings help to expedite the timeline of construction.

- Provide the fabricator with sufficient detail to ensure that steel elements are structurally sound and adhere to all necessary safety, quality and project standards.

- Reduce, or even eliminate, fabrication rework by resolving issues and clashes early on. As such, unnecessary expenditure on additional labor and materials are avoided.

How Design Drawings are Translated into Shop Drawings

In recent times, due to pressure on engineers as well as budget cuts, the quality of design deliverables has been less than desirable. Accurately translating design drawings into shop drawings is not simply a matter of plugging in the dimensions of design drawings; far more information and expertise is required.

That’s why it’s important to have the right team of experts with the appropriate technical expertise, who can decipher design intent and bring the project concept to life. Steel detailers must be able to take design drawings and integrate them into a 3D model, identifying and rectifying issues and clashes, to produce highly accurate 2D shop drawings that enable superior quality fabrication.

Conclusion

Design drawings and shop drawings both play an essential role in the lifecycle of steelwork—whether it is for a bridge, stadium, tank or pipework. Design drawings enable an architect or engineer to communicate their vision for a project. While shop drawings deliver the in-depth instructions and specifications required by a fabricator to supply structurally sound, millimeter-perfect steelwork.

Accurately translating design drawings into shop drawings requires vast skill and expertise. DBM Vircon’s innovative software and suite of technologically-advanced programs can transform high-level design intent into a workable set of fabrication instructions. By optimizing early stage designs, DBM Vircon’s services are crucial for identifying and addressing any issues in the design process at an early stage, which ensures that a project runs to schedule and on budget.