3D Structural Steel Detailing & Modeling Services

Making Design Constructible

DBM Vircon’s expert steel detailers make design constructible, translating information from clients and designers into live, data-centric 3D models and accurate shop drawings.

With expertise in complex projects and a focus on leading-edge technology, our approach reduces human error, all but eliminates rework and schedule delays, and minimizes the communication breakdowns typical of a traditional 2D environment. The result? Scheduling and cost certainty for the entire project team.

We go beyond traditional detailing to deliver full lifecycle solutions. Our customized proprietary workflows for Tekla, Navisworks, Rhino and other software deliver everything from 3D concept visualizations, and easily fabricated and erected build-ready plans, through to intelligent models for long-term asset management.

Structural Steel for:

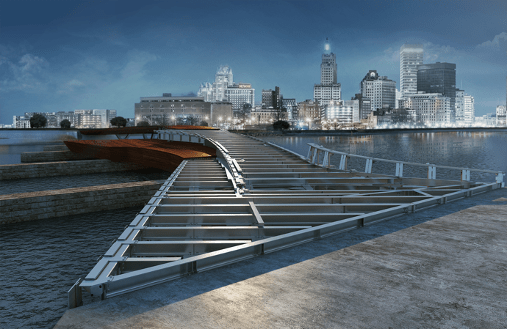

Bridges

As one of the first adopters of Tekla 3D modeling software for bridges, our 3D bridge modeling capabilities bring your concepts to life. Combining automated, accurate geometry with innovative software customized in-house, our whole of lifecycle approach increases construction efficiency, minimizes waste, and mitigates risk.

DBM Vircon’s numerical approach to Bridge Information Modeling (BrIM) produces precise models that match design intent for highly constructible bridge geometry. Early engagement and value engineering ensure important questions are answered upfront. This slashes rework, reduces health, safety and environmental risks, and provides certainty for material orders, costs and schedules.

Having successfully completed over 400 bridge projects globally since 1979, our unique combination of experience, expertise and technology enables us to turn complex data streams into intelligent, fit-for-purpose, context-rich models that reduce project timeframes and sure up project budgets.

Featured Projects

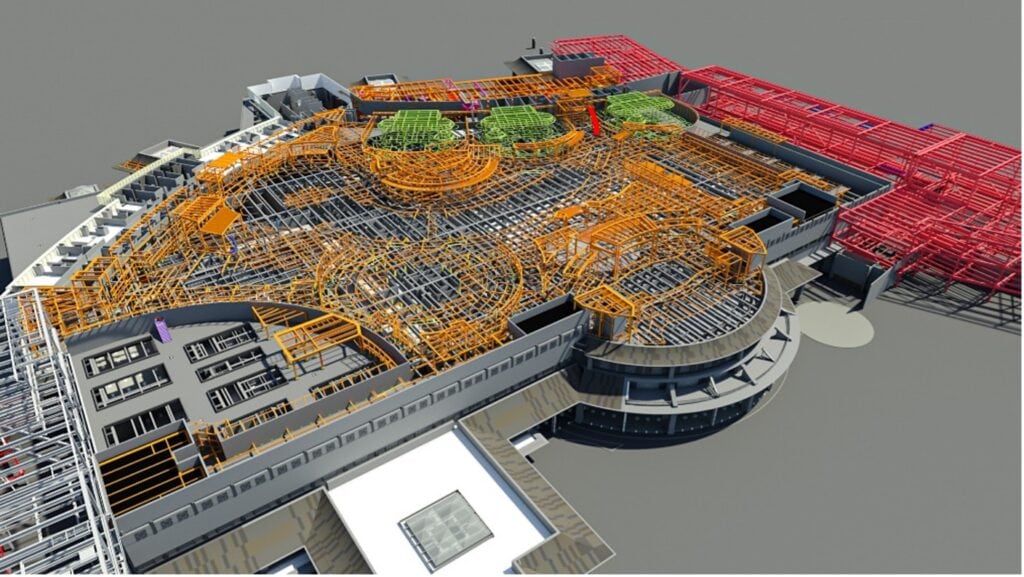

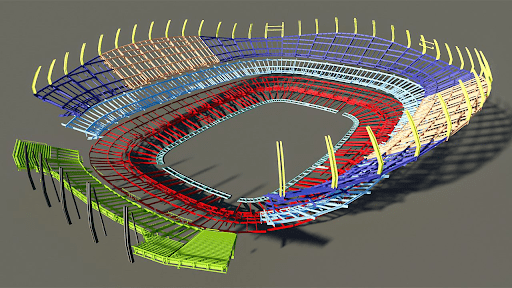

Commercial

From world-class stadiums to pioneering high-rise towers, DBM Vircon applies its 55 years of global modeling and detailing expertise to help streamline and de-risk the construction of complex commercial projects.

Unlike traditional production detailing, our proactive, collaborative approach and emphasis on early engagement drives each project. DBM Vircon’s project managers can work alongside your design team to help make the decisions with the greatest impact on cost and schedule.

Our cutting-edge technology—with features like electronic in-model review, custom reporting, automation and the ultimate quality control systems—embeds efficiency into the planning and construction of commercial projects.

Our deliverables add value far beyond standard shop drawings.

Featured Projects

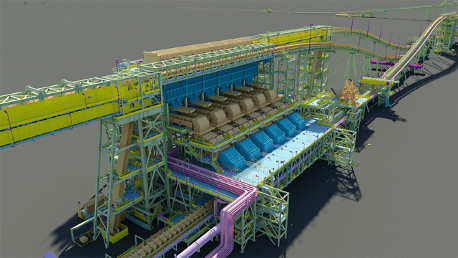

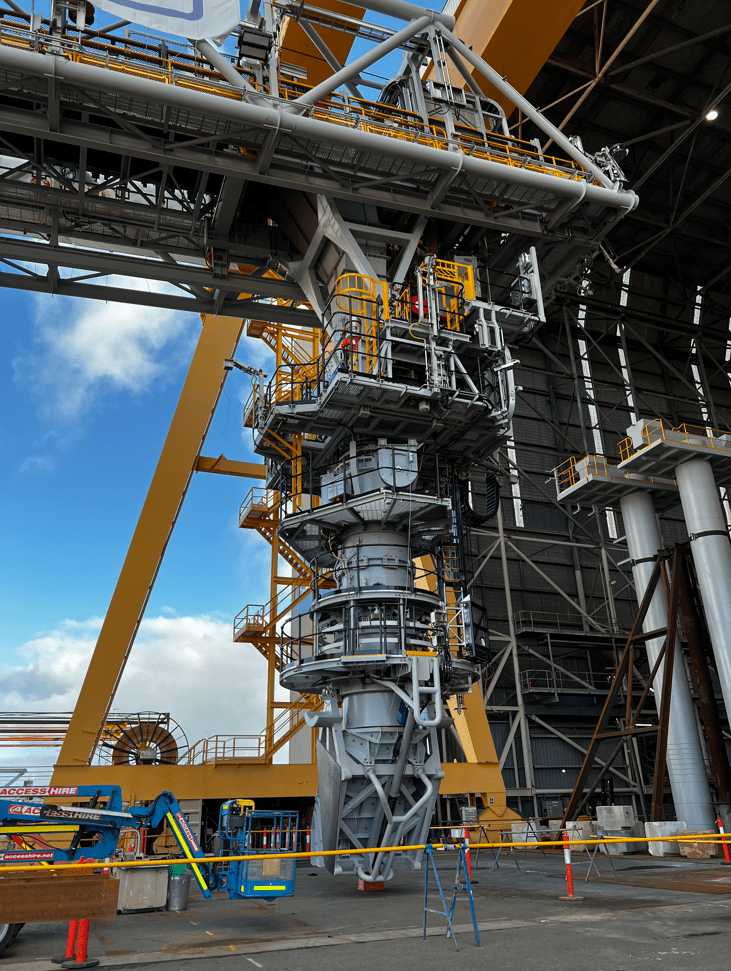

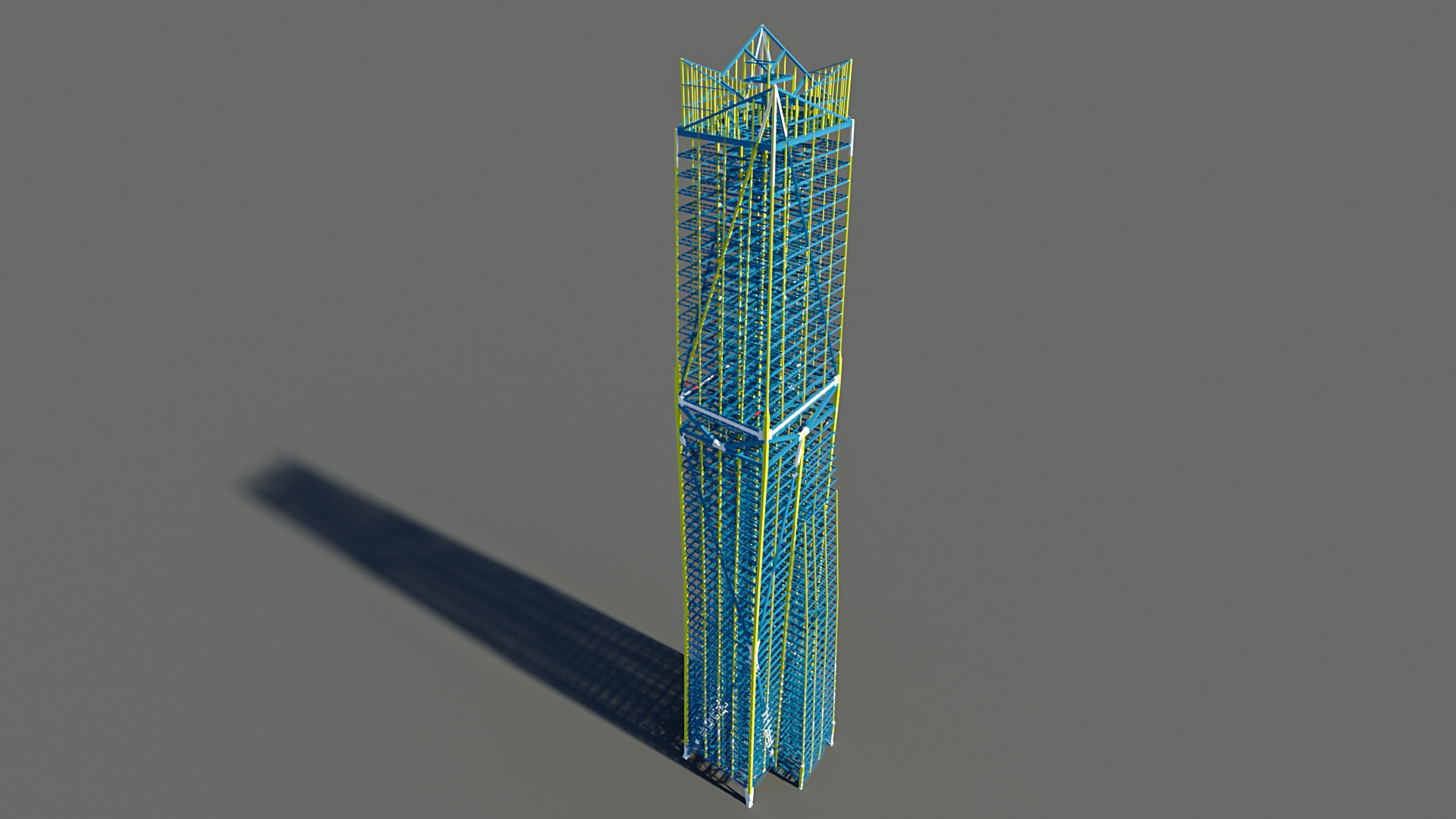

Industrial

DBM Vircon has provided design, detailing and integrated project services to the global mining, minerals processing and oil and gas industries for over 40 years. Leveraging the latest integrated software solutions and processes, our collaborative approach delivers cost and schedule certainty and improves site readiness.

Whether it’s developing designs for large mining projects, providing traditional detailing services for material handling infrastructure (like crushing and screening facilities, conveyor systems and transfer stations), or undertaking engineering reviews for complex industrial equipment (like stackers, reclaimers), we can help.

Featured Projects

Design Assist

Design assist helps bridge the gap between concept, engineering and fabrication. Utilizing collaborative techniques like early engagement, design development, and integrated design-detailing, we ensure all project stakeholders have a clear, unified understanding of design intent. This delivers more definitive early stage designs, minimizing costly changes during fabrication and erection.

Working closely with the fabricator and engineer, we can help evolve your design and provide fabrication and erection solutions, whether it be modularization of the steelwork, full trusses that need to be craned into position, or bridge geometry. We can even suggest design solutions, such as the appropriate venting requirements for finishes like galvanizing.

All this streamlines the fabrication and erection process for an efficient, on-time and on-budget build.

Featured Projects

-

Hong Kong

Hong Kong International Airport 3 Runway Concourse

With a project capex of $US18 billion US dollars, Hong Kong International Airport (HKIA) is Hong Kong’s largest ever infrastructure spend and DBM Vircon’s largest ever project in Asia.

With a project capex of $US18 billion US dollars, Hong Kong International Airport (HKIA) is Hong Kong’s largest ever infrastructure spend and DBM Vircon’s largest ever project in Asia. To meet future air traffic growth and maintain Hong Kong’s competitiveness as an international aviation hub, Airport Authority Hong Kong has embarked upon a major expansion project that will see Hong HKIA become a Three-runway System (3RS).

The 3RS project is more than a new runway. Its scale is almost equivalent to building a new airport next to the existing one. A key element of the project...

-

Mackay, Queensland, Australia

Shiploader and Berth Replacement (SABR)

The Hay Point Coal Terminal, owned and operated by BHP Mitsubishi Alliance (BMA), is one of the largest and most efficient coal terminals in the world.

Hay Point Coal Terminal has purpose-built rail in-loading facilities, on-shore stockpile yards, and offshore wharves. The offshore wharves are serviced by conveyor systems, supported on jetties, which run out to sea and allow loading in deep water. The Hay Point Coal Terminal is approximately 1.8km offshore and has three shiploaders.

Situated about 40 kilometers south of Mackay, Australia, the Hay Point Coal Terminal, owned and operated by BHP Mitsubishi Alliance (BMA), is one of the largest and most efficient coal terminals in the world.

Hay Point Coal Terminal has purpose-built rail in-loading facilities, on-shore stockpile yards, and offshore wharves. The offshore wharves are serviced by conveyor systems, supported on jetties, which run out to sea and allow loading in deep water. The Hay Point Coal Terminal is approxim...

-

San Francisco, California, USA

181 Fremont

181 Fremont contains office space on the lower 33 floors, and residential units and amenities including a two-story open-air terrace on the upper 15 floors. The building has a direct connection to the rooftop park atop the adjacent Transbay Transit Center from the fifth floor. The structure uses a traditi...

-

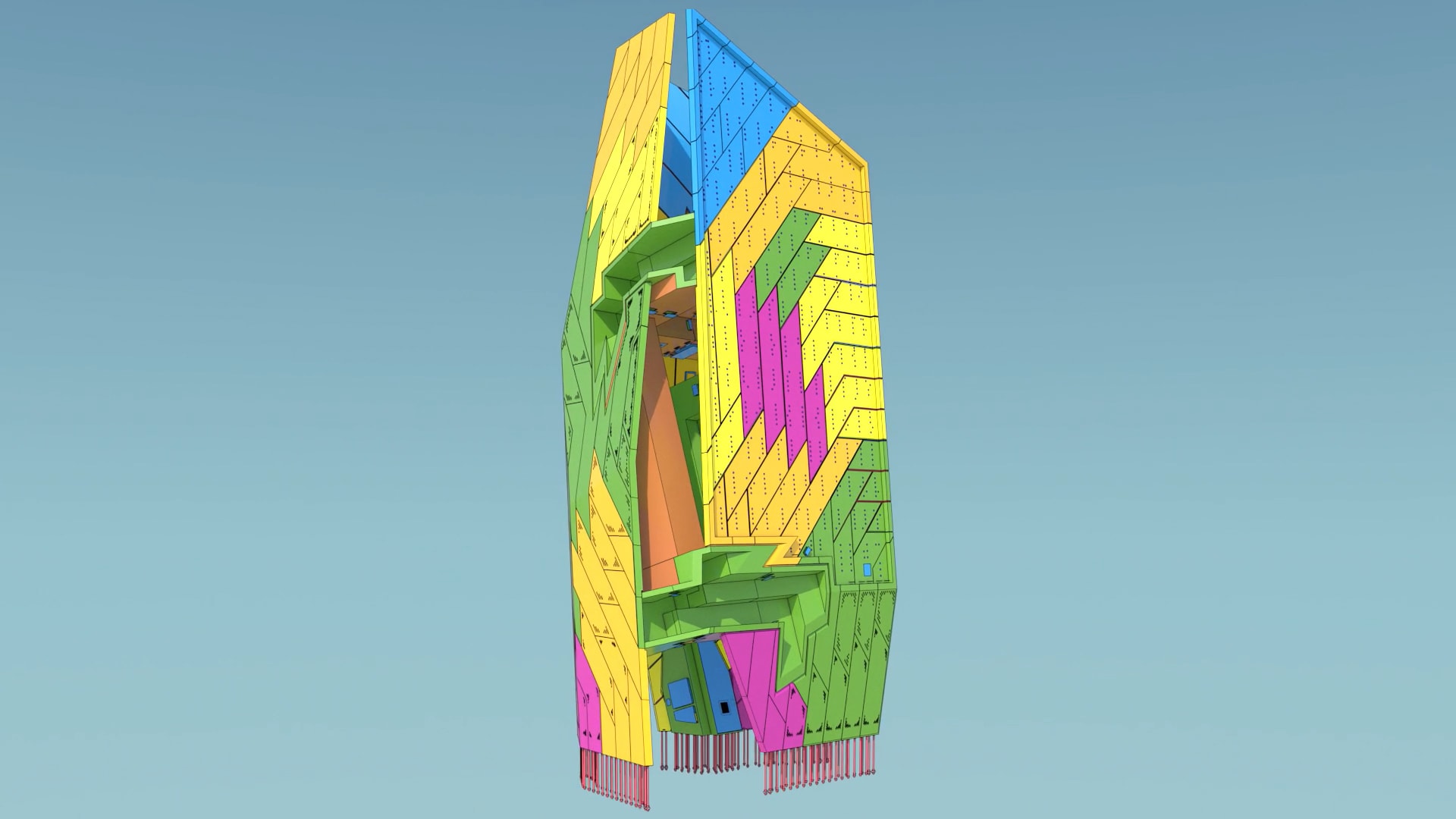

West Hollywood, California

The West Hollywood Sunset Spectacular

The West Hollywood Sunset Spectacular is a multimedia billboard for the 21st century. It is comprised of four giant parts: three outer panels arranged in a triangular pattern, with a ‘tesseract’ nested inside. At 64 feet high, the huge billboard is made from perforated metal, with the east and west-facing outer petals featuring embedded high-resolution LED technology.

The West Hollywood Sunset Spectacular is a multimedia billboard for the 21st century. It is comprised of four giant parts: three outer panels arranged in a triangular pattern, with a ‘tesseract’ nested inside. At 64 feet high, the huge billboard is made from perforated metal, with the east and west-facing outer petals featuring embedded high-resolution LED technology.

The three towering petals surround a pedestrian-accessible central void. Suspended overhead is a sculptural entity that ap...