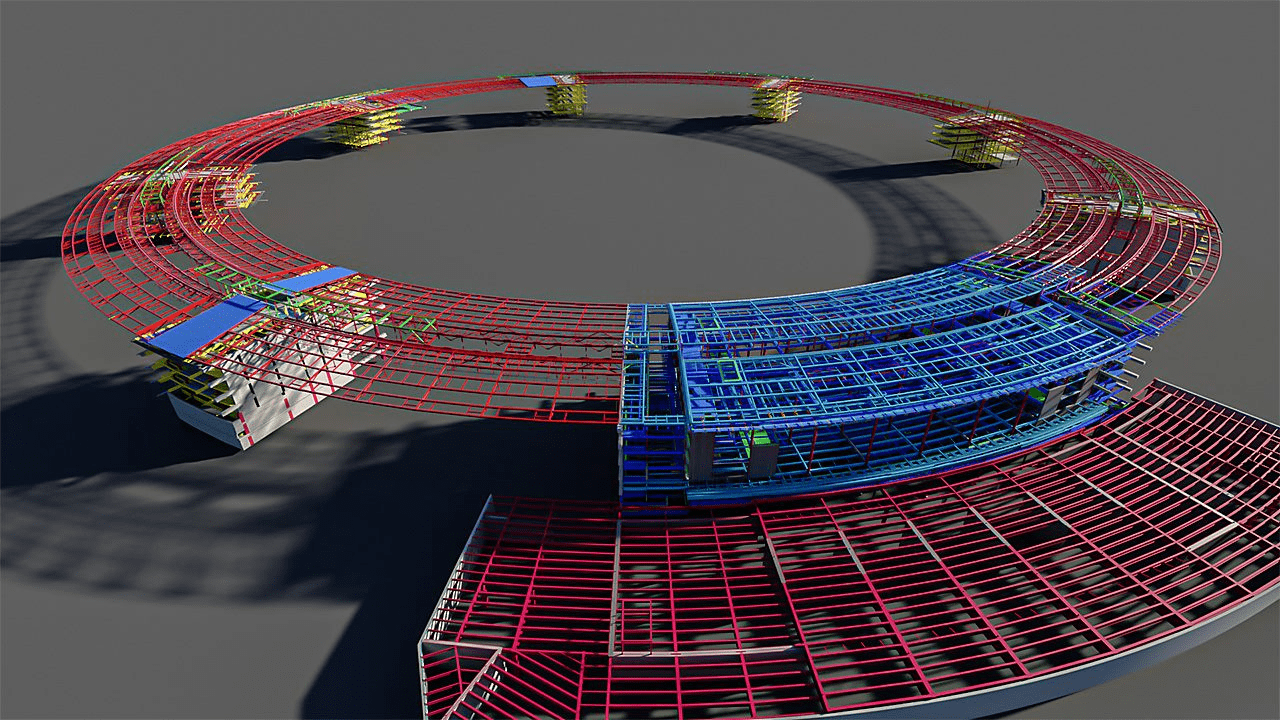

Pre-Construction Planning & Scheduling Services

Pre-construction planning can help you bridge the gap between design, engineering and fabrication. Utilizing collaborative techniques like early engagement, design development, design secondments and integrated design-detailing, DBM Vircon ensures that steelwork can be easily fabricated and erected for cost and scheduling certainty.

By undertaking this type of work early on, the steelwork can be assessed and confirmed during design rather than construction. DBM Vircon can pinpoint cost effective solutions that may not be feasible once construction commences.

Pre-construction planning helps eradicate the value engineering that is so typical of Design-Bid-Build projects. It helps keep your project on time and on budget, without the aesthetic, size or functionality compromises that are a necessary evil of the value engineering process.

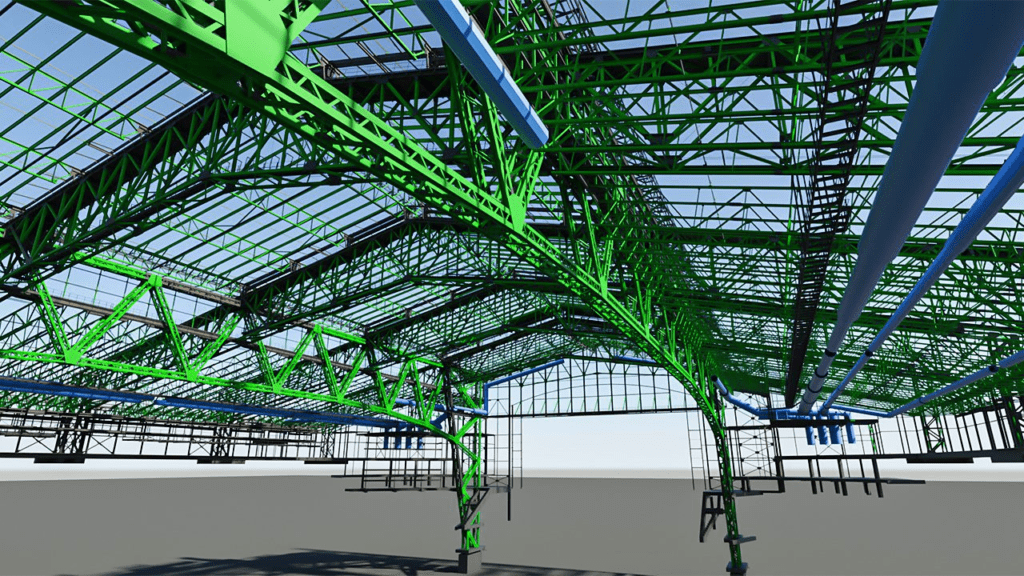

Design Assist

Design assist ensures all project stakeholders have a clear, unified understanding of design intent, so that early stage designs can be modified to achieve optimal steelwork outcomes and minimize costly changes during fabrication and erection.

Working closely with either the fabricator or engineer, we can help evolve your design and provide fabrication and erection solutions, whether it be modularization of the steelwork, full trusses that need to be craned into position or bridge geometry. We can even suggest design solutions, like appropriate venting requirements for finishes such as galvanizing.

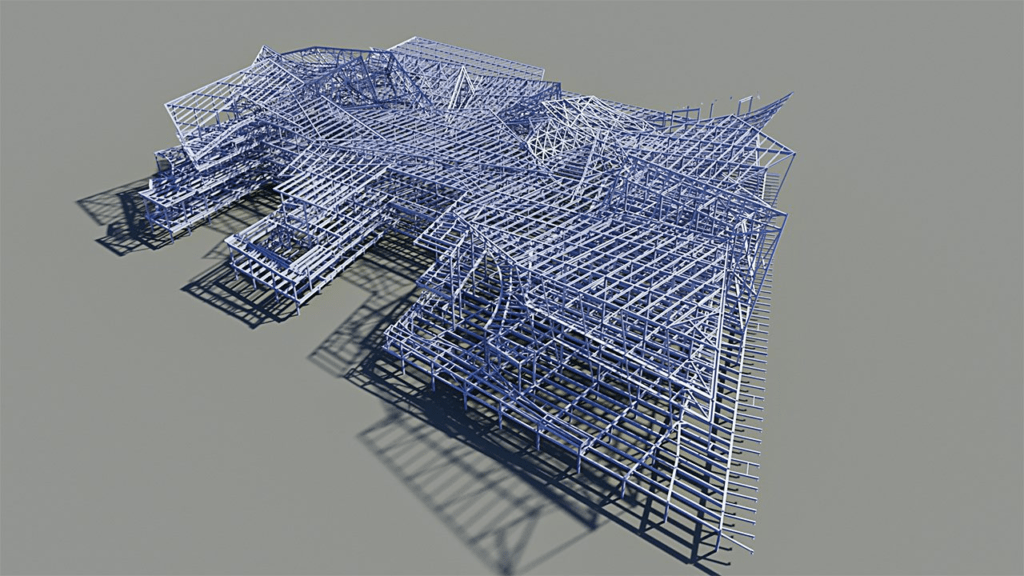

LOD 400 Connected Model

The engineering model (LOD 200) can be developed to approximately 80% complete, before it is handed over to DBM Vircon to lock in steel prices and expedite procurement. We can then develop an LOD 400 connected model that confirms factors like actual steelwork locations, clearances required, the types of welds and weld preparations to be used, and material thicknesses.

Unlike LOD 200 or 300 models, an LOD 400 model can actually be used for fabrication. Highly accurate erection plans can be generated from an LOD 400 model, virtually eliminating the standard RFI procedure.

Constructability Assessment

During our constructability assessments we work through every aspect of framing plans to ensure that steelwork can be easily fabricated and erected. This locks in cost and scheduling certainty. All steel members are reviewed for profile, location and elevation, and tagged in the model as approved, so that highly accurate erection plans can be generated.

Just some of the elements we assess for constructability include:

- Bolt clearance

- Weld accessibility

- Tolerance checks

- Crane reach and type

- Beam connection type and clearance

- Erection schemes and temporary structures

- Modular construction

- Panelization