Steel detailers play an essential role in the construction cycle. The detailed structural steel drawings produced by detailers ensure the accuracy, erectability and constructibility of structural steelwork, and the accuracy of elements such as connections. Together, this helps to avoid unnecessary shop and field rework, and prevents project delays.

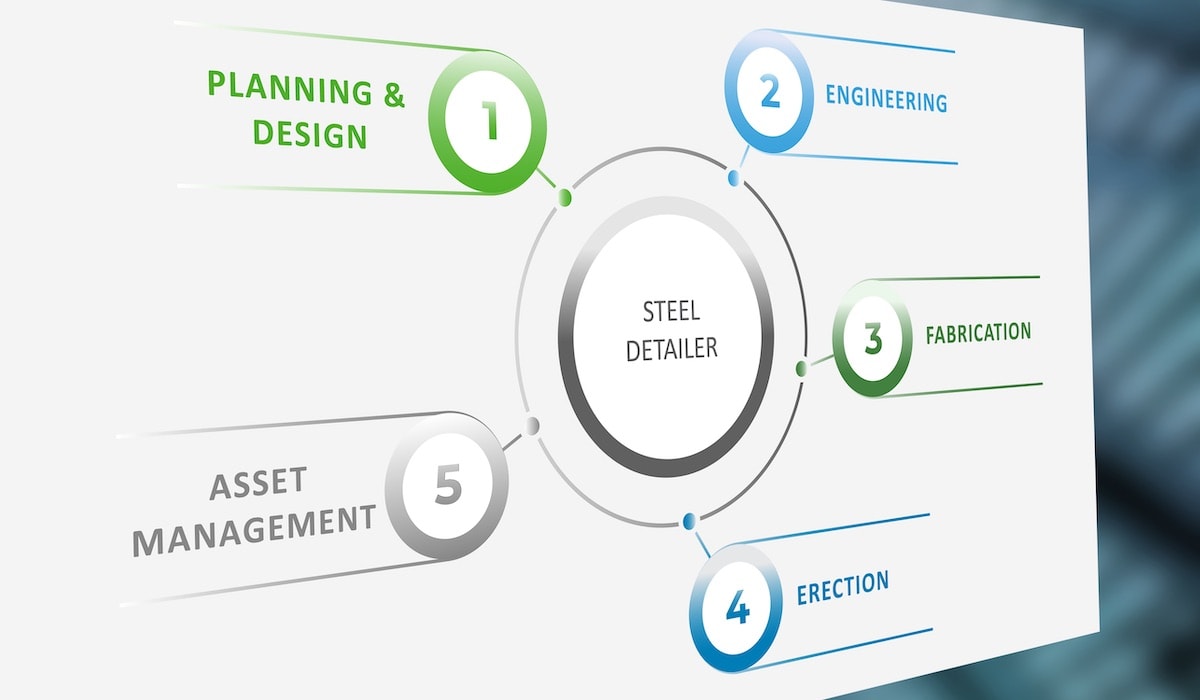

Traditionally, a steel detailer occupied quite a narrow role within the construction cycle, wedged between the engineer and the fabricator. However, with rapid advancements in technology and construction methodology, steel detailers have adopted a ‘whole of life’ service delivery approach.

Today, detailers are heavily involved in every stage of the construction cycle, from planning and design to construction and maintenance. As such, steel detailers collaborate closely with several project stakeholders, from architects and engineers, through to general contractors, fabricators and asset owners.

Planning and Design

Steel detailers work closely with architects during the planning and design phase of the construction cycle. In doing so, steel detailers are able to help architects validate and visualize design concepts. This ensures that mistakes, miscommunications and other clashes are mitigated early on in the construction lifecycle, preventing unnecessary rework, extended timeframes and additional labor.

With precise 3D renderings and walkthroughs, detailers can help architects to accurately illustrate and communicate design concepts to clients and other project stakeholders. These visualizations can even incorporate lifelike textures and details like light and shadows, so that clients can see the space from every possible angle and get a feel for elements like size and layout, expediting approvals.

Engineering

During the design phase, steel detailers help to mitigate the chaos and confusion that can arise between the engineering and fabrication processes. Steel detailers translate design intent into constructible shop drawings. These structural steel drawings contain all the information required to fabricate steelwork that is highly accurate and practical to manufacture.

Steel detailing also helps resolve engineering design conflicts, particularly in critical areas such as connections and joints, supporting structures and facades, as well as mechanical, electrical, plumbing and fire services.

When it comes to the engineering process, 2D technical drawings can often be the most time consuming. Steel detailers can automate much of this process, increasing productivity, reducing human error, and compressing project delivery timeframes.

Fabrication and Construction

During fabrication and construction, structural steel detailing helps to ensure that all steelwork is easy to assemble, install and erect.

Steel detailers help fabricators ensure that all steelwork is precise and exact to the millimeter. This is imperative, as inaccuracies, particularly regarding connection design, can require expensive rework, or even complete replacement. This can cause project delays or even complete site shutdowns. The use of precise structural steel drawings during fabrication and construction helps avoid these issues.

Using detailed and data rich models, steel detailers are able to generate highly detailed structural steel drawings that enable fabricators to utilize techniques such as prefabrication and modular construction. By designing, detailing and building offsite in a controlled environment, fabricators are able to reduce waste, as well as costs associated with labor and materials, while increasing efficiency.

If the industry, as a whole, can reduce or remove costly budget blow outs and project delays, the use of steel is likely to increase across high-rise and major infrastructure projects. Steel will also be more likely to become the material of choice for construction projects.

Maintenance and Asset Management

Structural steel detailing services are also valuable throughout the entire lifecycle of an asset, including ongoing maintenance and asset management.

For site shutdowns, highly accurate and detailed animations can help reduce schedule slippage and safety risks by ensuring that all stakeholders – which can be hundreds of people on large job sites – are engaged.

This technology also improves site safety by coordinating field tasks remotely, and implementing virtual walkthroughs of plants, facilities and mine sites for training purposes and fast, safe problem resolution. The use of virtual reality technology to animate and rehearse shutdown and maintenance procedures remotely improves site and employee safety.

Conclusion

Steel detailing is an integral part of the construction cycle for short, medium, and long-term projects. From the planning and design phase, to fabrication and erectability, a steel detailer’s job is essential.

DBM Vircon’s steel detailing is millimeter-perfect, with careful consideration of all stakeholder needs. We use advanced 3D renderings and modeling to meticulously plan out a project, and guarantee that all steelwork meets installation requirements.

Our collaborative approach also means that we serve as the central point of contact between architects, engineers and fabricators. This seeks to eliminate any potential breakdowns in communication, which may lead to costly errors. Our deep experience and in-depth expertise, which spans 45 years, allows us to deliver premium steelwork projects ahead of schedule.