In an era marked by rapid technological evolution, the steel fabrication industry stands on the brink of transformative change. As new tools and processes challenge traditional norms, professionals are grappling with the implications for age-old practices such as shop drawings.

One example of a project leading the charge in the realm of fabrication advancements is the monumental West Hollywood Sunset Spectacular. This state-of-the-art undertaking showcases how DBM Vircon is pioneering model-to-fabrication technology advancements. It poses the pivotal question: are we heading towards an era where traditional shop drawings might no longer be necessary?

Case Study: A Spectacular Results Without Shop Drawings

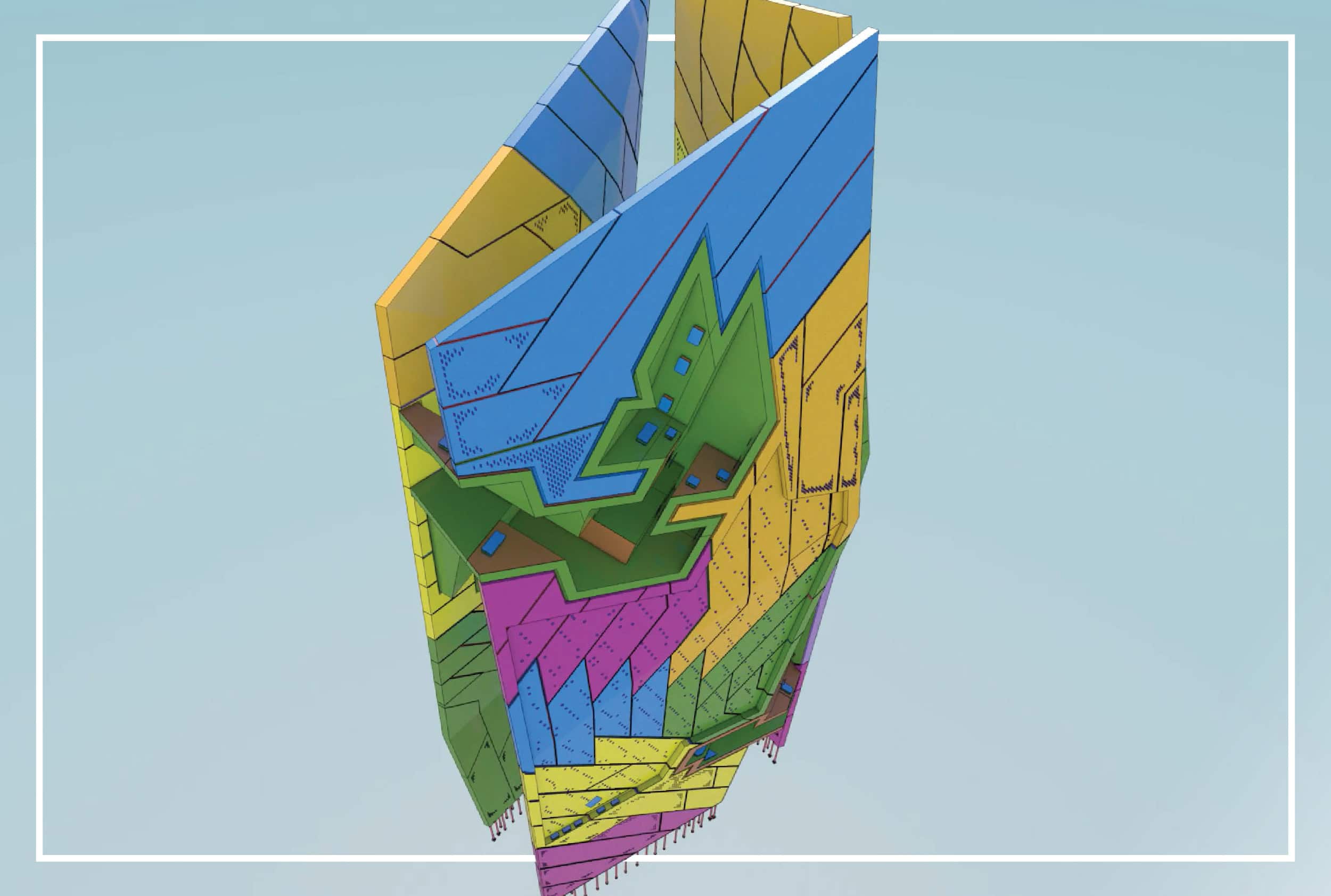

The West Hollywood Sunset Spectacular is a multimedia billboard for the 21st century. It is comprised of four giant parts: three outer panels arranged in a triangular pattern, with a ‘tesseract’ nested inside. At 67 feet high, the huge billboard is made from 100 tons of stainless steel, with the east and west-facing outer petals featuring embedded high-resolution LED technology.

The three towering petals surround a pedestrian-accessible central void. Suspended overhead is a sculptural entity that holds and stabilizes the three sides of the billboard.

With an accelerated construction schedule due to commercial considerations, the shop drawing phase was completely eradicated from this project. To achieve this streamlined delivery methodology, DBM Vircon tailored the modeling and electronic approval process for the components required for the billboard.

Rather than producing assembly drawings, part drawings and erection sheets, DBM Vircon utilized the Tekla model to generate STEP files for approval by the architect and engineer. This effectively removed the need to produce assembly drawings, part drawings and erection sheets. The STEP files were then used by the fabricator to nest, laser cut and weld the stainless steel plates required to fabricate the super component assemblies.

Technology Shifts

Over the last two decades, steel fabrication advancements have not had a transformational impact on traditional shop drawing presentation requirements. The proliferation of technology like CNC beam lines and part processing machinery has not changed the essential intricacies inherent in shop drawings. After all, it is these intricate details that enable fabricators to complete the critical quality assurance process before steel is transported to site.

However, technology advancements have subtly reshaped the deliverables for steel detailers. There has been a clear shift towards detailers needing to invest more of their efforts to completing a precise and data rich 3D model environment to support fabrication management software, CNC machinery, robotics, and advanced survey and laser layout equipment. This shift has, perhaps unintentionally, led to varied quality in shop drawing outputs across the industry and, therefore an evolving and critical need for accurate, data-centric steel fabrication models.

Key Drivers in Phasing Out Traditional Shop Drawings

With the latest round of steel fabrication advancements, this slip in quality, has the potential to completely remove the need to deliver shop drawings. The latest technological advancements, emphasized by projects like the Sunset Spectacular, hint at a future where shop drawings may not be necessary. Key factors include:

- Part Layout Technology: Innovations such as shop floor augmented reality headsets, laser overlays on steel, and fully automated assembly fitting and welding robots are redefining detailer’s deliverables. These tools, which leverage and interpret data—such as dimensions, welds and hole criteria—directly from detailed 3D models might soon obviate the need for traditional shop drawings for certain tasks.

- Quality Assurance Technology: Modern quality assurance processes incorporate technologies like augmented reality headsets and laser scanning equipment for automated inspections. The ability to juxtapose the 3D model assembly with the physical fabricated assembly on the shop floor could further diminish the reliance on traditional shop drawings.

The Continued Relevance of Traditional Practices

However, it might be premature to suggest that traditional shop drawings have become entirely redundant. Certain factors still underscore their importance:

- Machinery Limitations: Robotic equipment, while advanced, has its constraints in handling the vast range of shapes and sizes unique to structural steel construction. Certain dimensions and profile size limitations, particularly those of complex structures like trusses, will continue to necessitate traditional shop drawings.

- Variability in Robotics: Not all robotic machines are designed equally. Depending on the specific machinery, there might be constraints related to weld type or size.

- Nuanced Notations: Non typical notation is yet to be solved through technology, such as no-paint zones, specific faying surface preparation criteria, and protected zones. These elements will continue to warrant communication via traditional shop drawing methods.

- Government Agencies: The continued requirement from government agencies (i.e., DOTs) for traditional shop drawing approval submissions and archiving hard copies of project as-builts. For example, in the US, although states are starting to move towards a more digital process, traditional shop drawings must still be submitted for both approval review and record keeping on all government projects. While governments may adopt digital twin submission for particular projects in the future, this is likely many years away—if at all.

- QA/QC Reviews: Even though the use of Robotic Total Station and Laser Scanning is slowly becoming more common for validation, the use of physical drawings and manual measurements is still widely used throughout the fabrication industry for quality reviews and certification.

The real intrigue lies in the future: How will these advancements open doors for value engineering collaborations between fabricators, detailers, design teams, owners, general contractors and construction managers? It is evident that the role of, and deliverables produced by, steel detailers is undergoing another transformation. For detailers poised at this juncture, embracing the rigor and precision in 3D modeling is not just recommended but essential to remain at the forefront of this evolving industry.