3D Rebar & Reinforced Concrete Modeling & Detailing Services

With industry leading expertise in estimating, detailing, and modeling of complex reinforced concrete construction projects, DBM Vircon plays a pivotal role in helping move projects from the design phase to the construction phase. Having successfully delivered iconic projects globally in various sectors around the world, you can confidently partner with us to support all your reinforced concrete modeling, detailing, and estimating needs.

Supplemented by stringent QA/QC procedures, we can help eliminate field placement errors, while allowing information transfer among project stakeholders to help validate project details. This results in reduced issues, so rebar fabrication and assembly can be expedited with fewer changes in field.

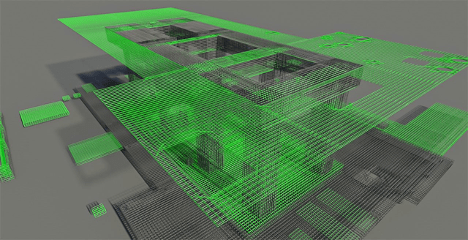

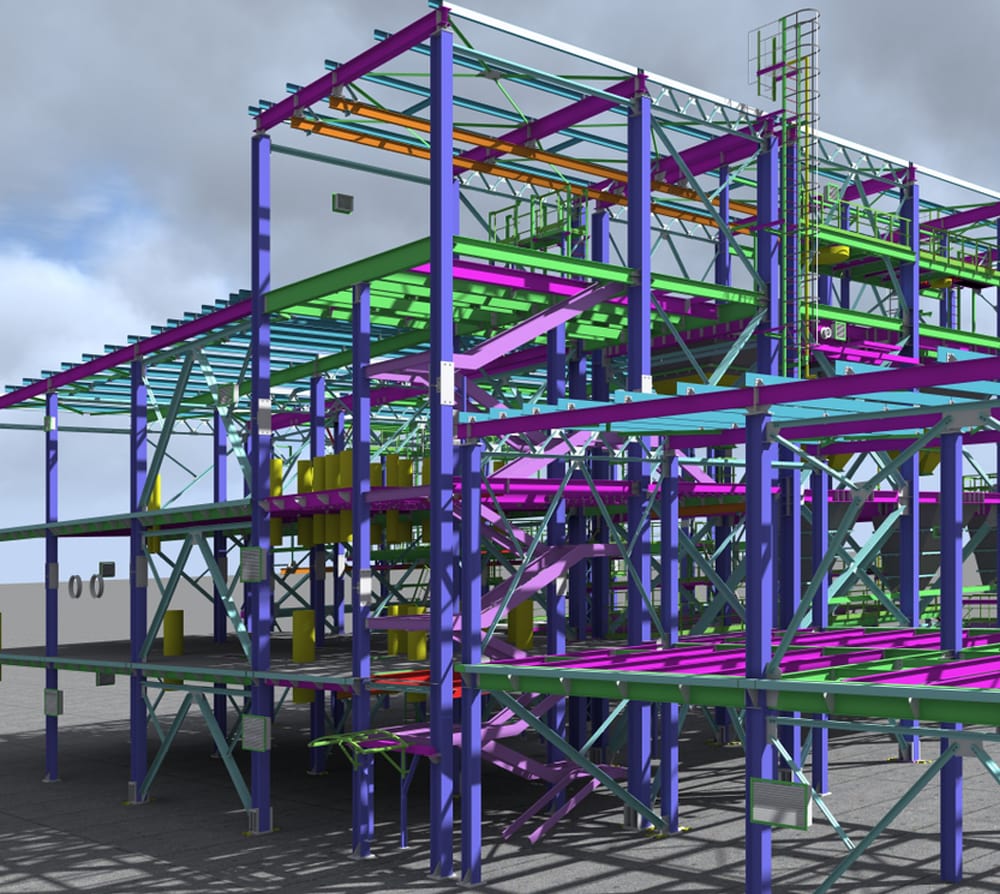

3D Modeling

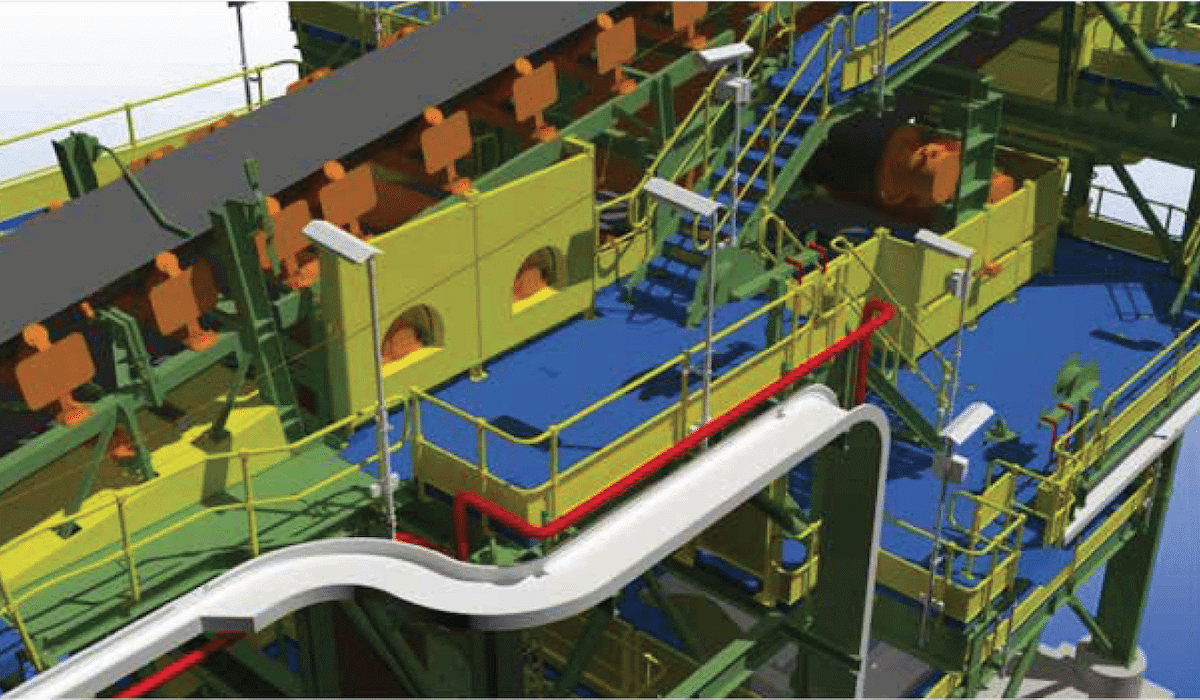

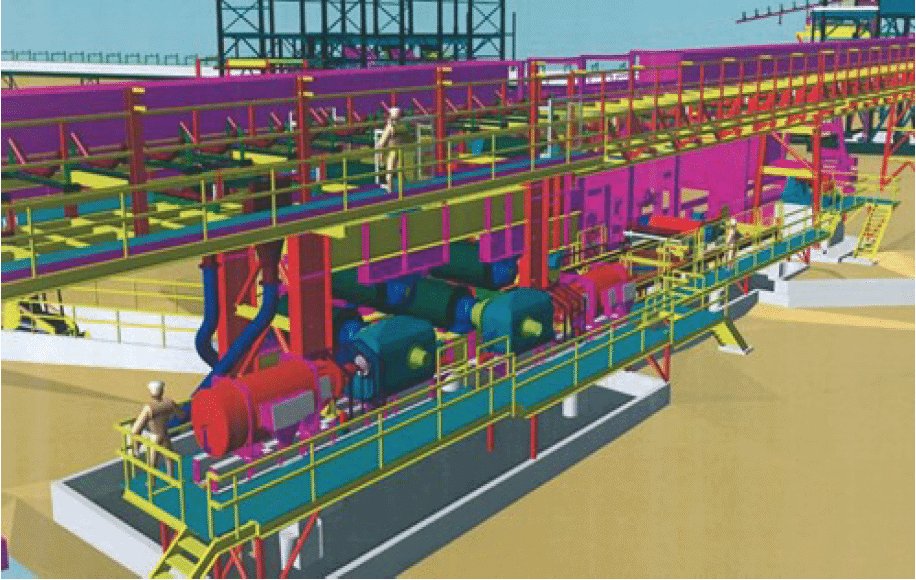

Our 3D concrete and rebar modeling integrates data for on and off-site planning, procurement, fabrication and erection of concrete and rebar for all types of projects. By introducing rebar detailing early in the design phase of your project, DBM Vircon can ensure the predictability and accuracy of the drawings and shop-bar ready lists. Better 3D modeling visualization and collaboration means fewer revisions and mitigated risks due to fewer unknowns, and a faster construction time due to less field coordination and downtime.

Featured Projects

Comprehensive reinforced concrete models

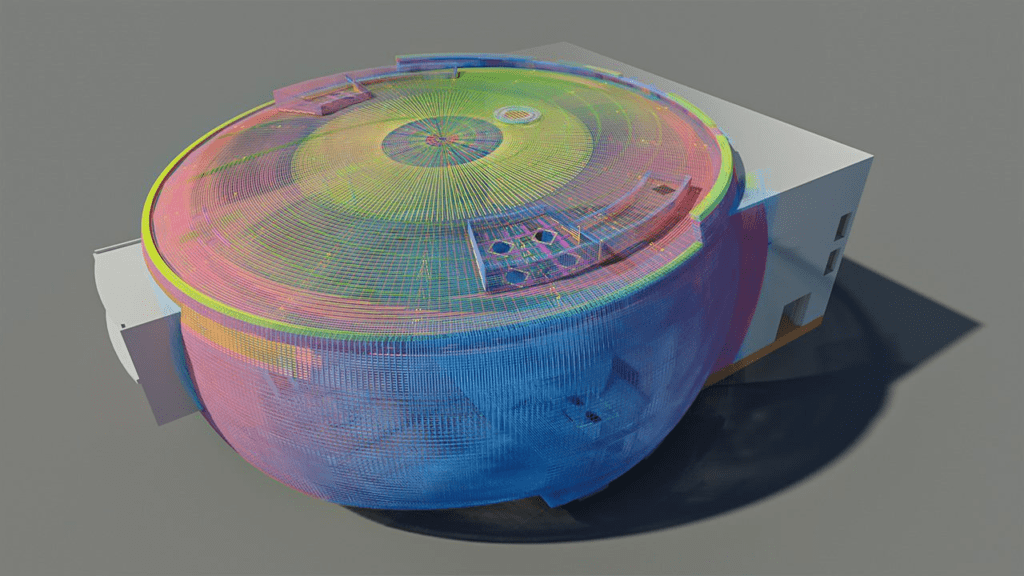

Whether it’s cast-in-place culverts, pre-stressed bridge girders, precast parking garages, composite stadium construction, mega infrastructure projects, or tall skyscrapers, our experienced team is well positioned to support all concrete and rebar modeling, detailing, and estimating needs.

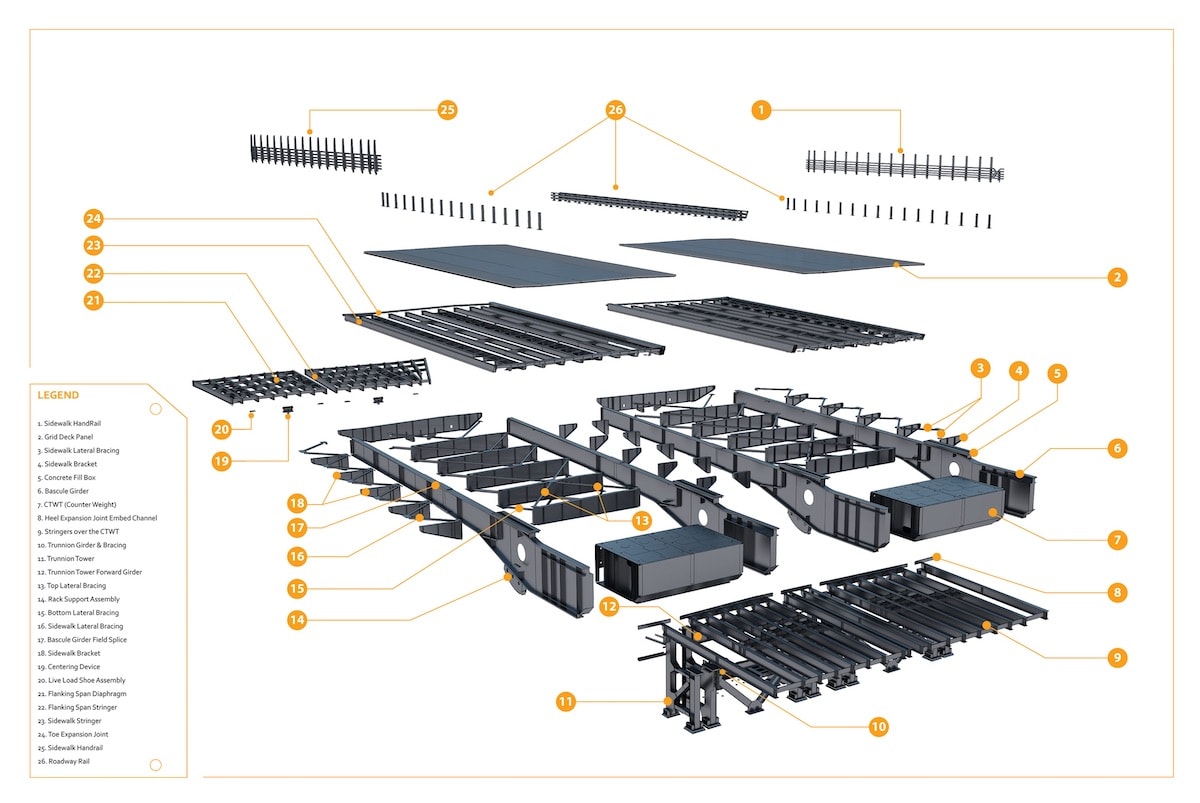

Our clear and comprehensive reinforced concrete models and/or rebar placing drawings allow extensive design communication, coordination, and information transfer among project stakeholders to help validate project details. This results in reduced ambiguities, fewer field changes and improved quality while enabling faster rebar fabrication and nassembly leading to expedited erection of reinforced concrete structures.

Our accurate bar lists and bar bending schedules, generated from our models and drawings, facilitate scrap reduction and diminished waste, allowing for productivity gains while minimizing environmental impact.

3D Modelling

DBM Vircon can provide data-rich concrete and rebar models that facilitate clear design communication, coordination, and information transfer. With precise 3D modeling, we integrate intelligent data for accurate on and off-site planning, procurement, fabrication, and erection of concrete and rebar for all types of projects.

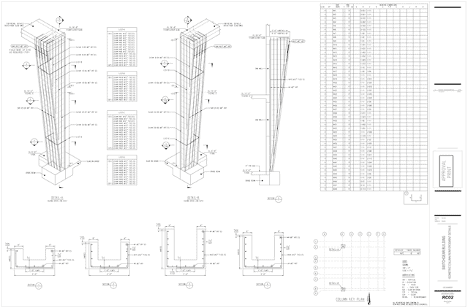

2D Detailing

Our comprehensive rebar field placement and shop drawings include all information necessary for complete fabrication, ordering and placing of all reinforcing steel, bar support systems, and accessories. Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars. Our accurate bar listing and bending schedules facilitate simplified shop fabrication and helps to reduce scrap material.

Featured Projects

Estimating

With the capacity to estimate large tonnages of rebar, our clients have come to rely on our timely and accurate data. Our comprehensive, bar-by-bar quantity take-offs provide detailed, accurate quotes for placing successful bids. On on-going jobs, our experienced estimating team has ability to provide actual detailed versus estimate weight tracking, along with in-depth change order and variation reviews.

Featured Projects