When it comes to complex construction projects, construction professionals want to ensure that the project is completed on time, within budget, and to the highest quality standards. One of the key products in most construction projects that causes schedule and cost risk is rebar and its associated trades.

Traditionally, rebar scheduling and detailing has not embraced 3D modelling software as readily as other disciplines like structural steelwork. The shift from 2D to 3D in those disciplines began gradually in the late 1990s, however, thanks to recent advancements in 3D modelling software, leading rebar detailing companies have seized the opportunity to transition to 3D solutions. In the past few years, these 3D softwares have undergone significant development, integrating rebar modelling with other disciplines and enabling service providers to offer increasingly efficient and cost-effective solutions for complex construction projects.

While traditional 2D scheduling has been the norm for rebar detailing and scheduling, it comes with inherent challenges and limitations that can introduce significant schedule and cost risks on complex construction projects.

2D drawings often struggle to present the complex geometry on some construction projects. The representation of rebar elements in 2D can lead to ambiguity and misinterpretation, making it challenging to visualize the project. Consequently, errors in rebar detailing may go unnoticed until construction is underway, leading to costly rework, project delays, and potential safety concerns. By understanding the limitations of traditional 2D scheduling, it becomes evident that a shift in the workflow and construction methodology is necessary.

Using 3D rebar modelling rather than traditional 2D scheduling may provide construction professionals with improved transparency, improved accuracy and proactive problem and coordination solutions. While 2D detailers or in-house scheduling resources may seem like cost-effective solutions, on complex projects, the benefits of using a 3D rebar modelling partner far outweigh the savings that can be achieved by traditional 2D workflows.

Some of the key advantages of using a reputable rebar modelling company for 3D rebar detailing services include:

Increased Accuracy

3D modelling software allows for greater accuracy in the placement and sizing of rebar. By creating a millimetre perfect 3D model of the structure, the rebar can be placed precisely and with greater accuracy compared with a 2D drawing. An example of where this is highly advantageous is for infrastructure upgrade projects where existing elements need to interface with new elements. As-built conditions are frequently not as perfect as the design may assume. Through utilising laser scanning and point cloud models, accurate 3D rebar models can be interfaced with as-built conditions to ensure accurate planning and placement of rebar.

Improved Visualisation

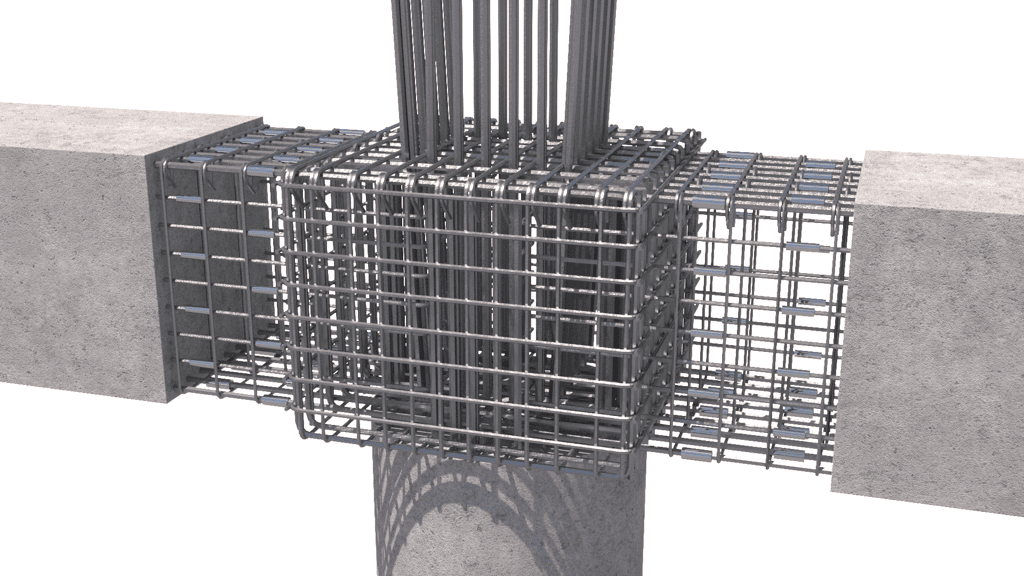

3D modelling allows for improved visualisation of the reinforcing steel, which can help identify potential clashing or issues before construction begins. By using a 3D model, contractors can identify any rebar clashes and adjust the design before placing the rebar.

Better Collaboration and Coordination

3D rebar modelling allows for better communication and collaboration with all stakeholders, including the project owner, consultants, and contractors. By sharing a common 3D model, stakeholders can work together more effectively and ensure seamless coordination between various disciplines. An example of this benefit has been seen throughout the construction of the Kangaroo Point Green Bridge in Brisbane, Queensland. The project relied on 3D rebar modelling to develop a comprehensive model encompassing the bridge’s seven intricate pile caps, pier columns, eight deck spans, and five diaphragms. The intricate geometries of these bridge elements would have posed significant challenges and cost implications without the utilisation of a 3D model. By leveraging the 3D models, contractors were able to proactively identify potential clashes, coordination and constructability issues, make necessary design adjustments prior to construction commencement, thereby minimising errors, mitigating cost overruns and streamlining the overall project timeline.

Intelligent Digital Delivery

3D rebar models allow construction professionals to utilize intelligent models and data contained within them to support its widespread use downstream from the design stage consistent with other design disciplines. Well controlled models and data enable construction professionals to hand over an accurate intelligent model at completion suitable for facilities management. Remote mining or industrial facilities are great examples of where there is considerable additional value realised by project owners in having increased access to reliable model data. Infrastructure projects additionally achieve value in later expansions and upgrades.

Improved Construction Sustainability

By optimising the use of rebar, 3D rebar modelling can help reduce waste and improve a project’s sustainability. This can in turn save on material costs, and guarantee procurement up front. For example, the construction of the new Chevron Tower in Perth, Western Australia, leveraged 3D rebar modelling to create a highly detailed model of the building’s structure. This model empowered the delivery team to proactively balance the incorporation of value engineering methodologies provided by the engineer to minimize rebar wastage with efficient rationalization of rebar design for site-based delivery efficiencies.

By utilizing 3D rebar modelling services, construction professionals can also create a competitive advantage in the industry. Clients are increasingly looking for contractors that can provide innovative solutions that increase efficiency and provide a more sustainable solution to minimize the environmental impact. By demonstrating a commitment to using the latest technology and best practices, contractors can position themselves as leaders in the industry and attract more clients.

The use of 3D rebar modelling offers significant advantages for complex construction projects, including increased accuracy, improved visualization, better collaboration, and reduced waste. By investing in a market leading rebar modelling company for these services, construction professionals can achieve these benefits while also ensuring the quality and reliability of the work.