When we look at the way industry has evolved over the last 10 years, one of the most significant changes has been the structure of engineering teams. The key role of Designer is increasingly rare. Traditionally, the Designer sat between the Engineer and the Detailer, and was tasked with expressing the engineering intent. Without this critical piece of the puzzle, there is no one to help bridge the gap between concept, engineering and fabrication.

This challenge is compounded by continued pressure on engineering teams to hand over drawings as quickly as possible to accelerate fabrication and construction commencement. The adage of ‘time is money’ is constricting engineering timeframes.

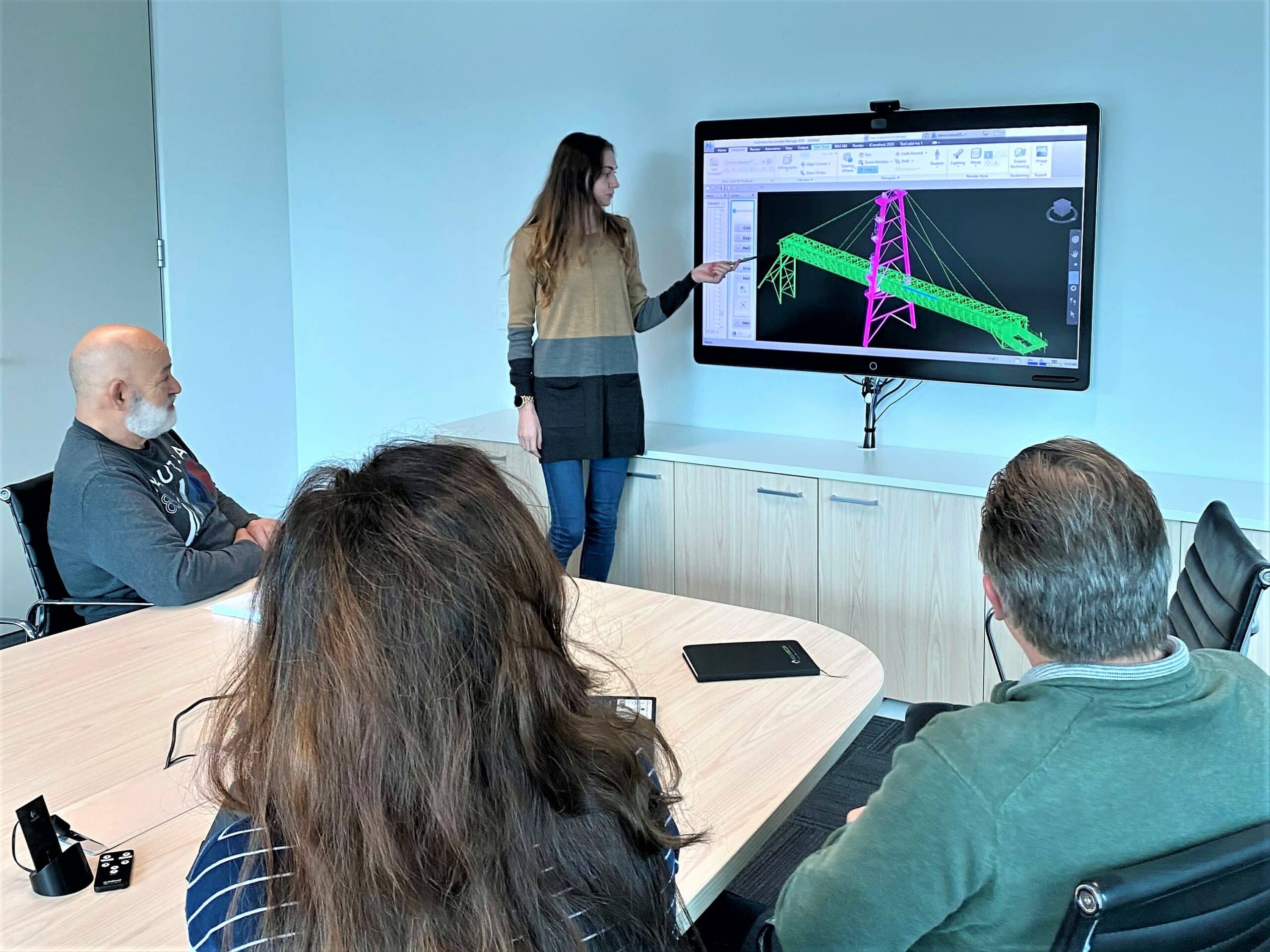

Changing roles and compressed project schedules necessitate collaboration between engineers, project owners and detailers. A collaborative approach affords myriad benefits. Engineering designs can be validated, visualised and communicated more efficiently, and clashes and constructibility issues identified earlier. This way, engineers can hand over drawings or models more quickly and fabricators can deliver accurate steelwork—the first time.

There are five key criteria for a successful collaborative engagement with engineers and project.

1) Early Engagement

Traditionally, modellers and detailers occupied quite a narrow role within the construction cycle, wedged between the engineer and the fabricator. Today, the earlier the detailer is involved in the project, the more collaborative the engagement, and the more beneficial the project outcome.

Early engagement enables detailers to translate design intent into constructible shop drawings or models. With the shop detailer concentrating on creating an accurate model, this leaves the designer free to concentrate on the design – with no one wasting their time. Mistakes, miscommunications and other clashes can be mitigated early on in the construction lifecycle, preventing unnecessary rework, extended timeframes and additional labor.

2) A Multi-Disciplinary Approach

Detailing of major industrial and mining projects cannot focus solely on structural steelwork. It must consider all aspects of project delivery, from piping and mechanical inputs through to civil, plumbing and fire services. Successful collaborative delivery requires all disciplines to work together, with a clear, unified understanding of design milestones and requirements.

3. Clear Delineation of Data Requirements

Over the past few years, there has been an increasing focus on the production of not just shop drawings or models, but highly accurate, metadata rich 3D models. It is essential that clear data requirements are delineated at project commencement to ensure that long-term client objectives can be met.

For instance, if a Digital Twin is required for asset management purposes, BIM, Digital Engineering and IoT data sets must be defined, specified, and delivered correctly. The process for data capture, storage and governance must also be confirmed as early as possible. Retrospective application of data can be near impossible in some instances.

4) Fit-for-Purpose Co-Location Arrangements

Co-location of construction modelling teams with engineers can deliver both huge success and great failure—the outcome really is dependent on the specific circumstances of the project.

Co-location can help foster strong working relationships between project stakeholders. Stakeholders can quickly interact to prevent issues piling up, and constructability and erectability challenges are often resolved earlier in the design process.

However, long-term co-location can increase the quantum of design changes, simply because the accessibility of steel detailers means that it is fast and convenient to make those changes. Agreement on what design changes are necessary and a suitable cut off period for those changes help to ensure unnecessary delays in schedule.

Co-location works best when all project stakeholders have considered the timing, duration and size of the co-located team—the arrangement must be fit-for-purpose.

5) Honest Communication

It is imperative that all project stakeholders communicate their progress and pinch points honestly, accurately and efficiently. All stakeholders need to come together as a team to deliver the project as effectively as possible. Armed with an understanding of the project’s progress, all stakeholders are better placed to be more agile, supportive and proactive.

Article by David Dawson, Global General Manager – Industrial