The design, construction and long-term management of healthcare assets is subject to demanding and specific objectives: optimum health outcomes for patients, first-rate experiences for visitors, and superior quality working environments for doctors, nurses and other healthcare professionals. Governments and health authorities are facing rising costs that must be met with innovative solutions for the design, construction and operation of hospitals, medical centres and research institutes.

So, it comes as no surprise that most healthcare projects are designed digitally, through Building Information Modeling (BIM). When using BIM, it is vital that all project stakeholders understand the usability and limitations of the model. That’s where the LOD framework comes in.

In simplified terms, LOD indicates how much information is detailed in a 3D model and what data is accessible to the project team. It allows project stakeholders to view how the geometry and data associated with a specific element evolves throughout the design, construction and as-built process.

As an industry standard, the LOD framework clearly defines the development stages within BIM. It helps facilitate clear communication between architects, engineers, contractors, fabricators and asset managers—for accurate scheduling and procurement, faster construction, and reduced costs.

The Six Stages of LOD

The LOD framework was formally established by the American Institute of Architects (AIA) in 2008. Originally, LOD was defined as ‘Level of Detail’. However, over the intervening years, the acronym has since become associated with ‘Level of Development’. According to the AIA’s definition, there are six stages of LOD.

LOD 100 – Concept Design

Elements are represented generically (usually via 2D symbols) to provide a very basic idea of layout. There is no data on factors like orientation, size or shape. While all data should be treated as approximate only, LOD 100 models can be used to estimate cost per square metre and tonnage of HVAC.

LOD 200 – Schematic Design with Approximate Geometry

Elements are partially defined, with some data around quantity, shape, size and location. However, there is a considerable degree of estimation and all data should be treated as approximate only.

LOD 300 – Detailed Design with Precise Geometry

Elements are defined with specific geometric sizes, dimensions, orientation, location, and quantities. LOD 300 models can be used to generate shop and construction drawings.

LOD 350 – Construction Documentation with Precise Geometry and Connections

Precise information on how individual elements and components will be assembled and interconnected are added to the LOD 300 model. An LOD 350 model includes data around how different building elements will interact, such as how structural steel will interface with plumbing and electrical components.

LOD 400 – Fabrication Ready Documentation and Geometry

The data required to undertake fabrication of elements is added, such as bolts and holes, material thicknesses and weld types and preparations. Unlike LOD 300 or 350 models, LOD 400 models can be used for fabrication and assembly; elements can be measured directly from the model without needing to refer to any other information. Highly accurate erection plans can be generated from an LOD 400 model, virtually eliminating the standard RFI procedure.

LOD 500 – Operational or As-Built Model for Asset Management

The fully developed, functional model, showing the operational geometry of elements with verified information like manufacturer details, installation dates, and part and model numbers. LOD 500 models can be used asset management and ongoing maintenance.

How to Apply the LOD Framework to Your Healthcare Project

The construction and ongoing management of hospitals, clinics and medical research facilities requires certainty and precision. For complex healthcare assets, an LOD 350 model is recommended at a minimum—for several key reasons.

Confirm Constructability

An LOD 350 model can be used to ensure that steelwork can be easily fabricated and erected. This locks in cost and scheduling certainty. All steel members are reviewed for profile, location and elevation, and tagged in the model as approved, so that highly accurate erection plans can be generated. Elements like bolt clearance, weld accessibility, tolerances, crane reach, and beam connections can be assessed for constructability.

When these elements are assessed during pre-construction, cost-saving alterations can be made to the design before it’s too late—before the steel is ordered. For instance, a steel member size can be increased, rather than introducing more material or additional connections.

Simplify Complex Designs

Where healthcare projects are even more complex than usual, LOD 400 models can be used to overcome complexities, delivering significant cost savings. For example, due to the seismic activity, in a major hospital was designed with a first-of-its-kind vertical earthquake isolation system. The seismic resistant design featured Sideplate technology and Buckling-Restrained Braces, as well as an extremely complex base level that separated the building from the ground using more than 500 vertical shock absorbers.

The base level was a major challenge. All main framing members were built up plate girders, some designed with 4” thick flanges. The size of the plate girders created difficulties with available space for the structural nodes above the isolators, splice connections and penetrations to allow for services. An LOD 400 model was used to fine-tune the connections, splice locations and penetration locations to an achievable constructible base level.

Enhance Coordination of Service Zones and Exclusion Spaces

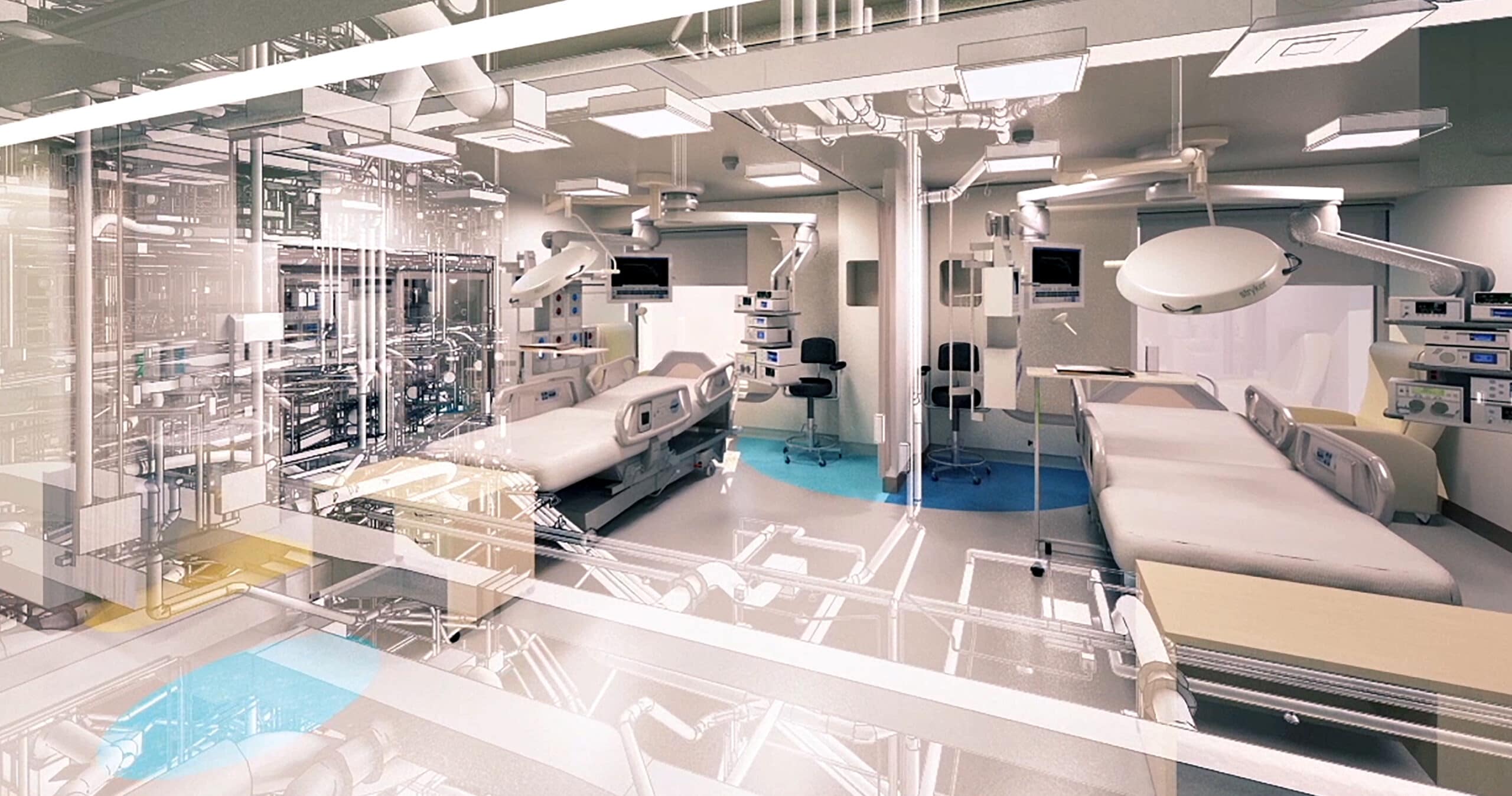

By creating service zones in an LOD 350 or LOD 400 model, critical-to-life services can be located in pre-allocated zones and clash detection activities can be run. With exclusion spaces incorporated into a project design from the outset, significant design changes can be mitigated. The design of critical-to-life services is essential—uninterrupted supply of electricity in operating theaters can be the difference between life and death.

Enable Innovative Construction Methodologies

Increasingly, hospital projects are leveraging the benefits of preconstructed, modularized bathrooms, surgical theaters, and services in a lift core or flue. For example, the reticulation of mechanical ductwork throughout a major hospital recently presented significant challenges for services coordination. Managing the flow and return of air from numerous plant rooms to each floor, ward and laboratory was particularly difficult due to the quantity of ductwork. These ducts needed to make their way through interstitial ceiling spaces, as well as tight cores and risers, with access penetrations on various sides. An LOD 400 model was used to test modularization possibilities. Both the ductwork and supporting structure could be coordinated and prefabricated off-site and craned into position. This saved significant time and cost.

Streamline Installation of Medical Equipment

The use of an LOD 350, LOD 400 or LOD 500 model to visualize multiple scenarios is particularly important for healthcare equipment specification. For example, MRI machines can weight up 40 tons and require special magnetic shielding, often through the use of faraday cages. This necessitates careful consideration of their location within a hospital, the impact the MRI might have on other services and equipment, and the installation and decommissioning process. An LOD 400 model enables rapid assessment of various design scenarios, enabling an installation team to perform their job quickly, safely and without impact on the finished construction.

Improve Safety

Increasingly, hospitals are implementing automated pharmacies serviced by unmanned autonomous vehicles. Medication is distributed directly to patient rooms via pneumatic tube systems to ensure patients receive the correct dosage. Autonomously Guided Vehicles (AGV) are also being introduced to move patient linen, meals and other equipment around hospitals. An LOD 350, LOD 400 or LOD 500 model can be used to cross-reference the travel paths of these autonomous vehicles to eradicate potentially dangerous accidents.