Wilshire Grand Hotel – Los Angeles

Written by: Gerard M. Neiblas, SE

Checking in at the Wilshire Grand Hotel in downtown Los Angeles is slightly more involved than checking in at a typical hotel. That’s because the lobby is at the top of the 73-story building, which also houses office space. When it opens this spring, it will be the tallest building west of Chicago at 1,100 ft and will be able to resists wind and seismic drifts with massive braces.

Outstanding Outriggers

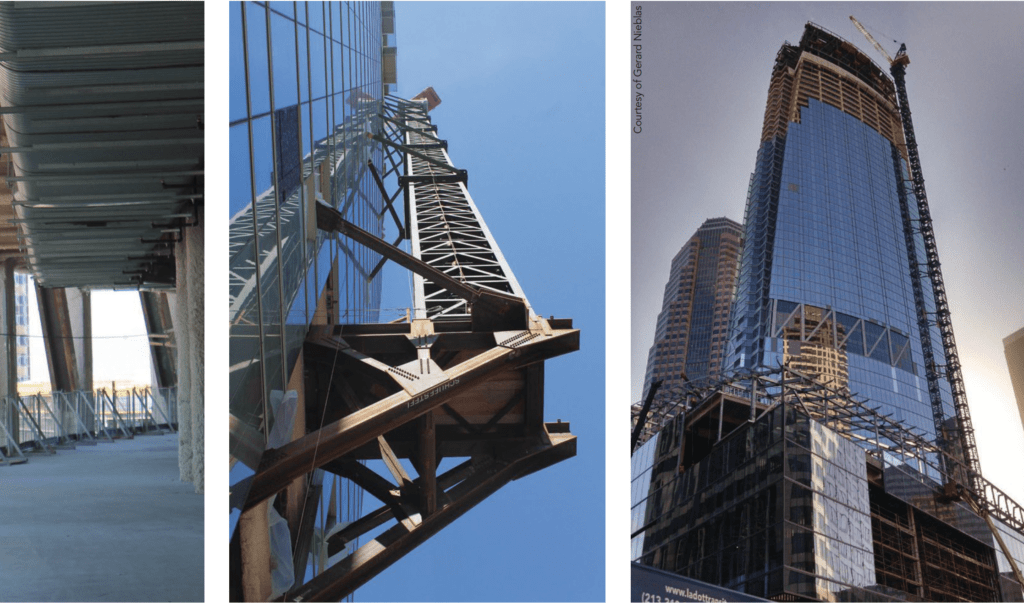

The building uses a structural steel frame to carry the gravity loads and a concrete shear wall core that serves as the lateral system. It in-corporates 19,000 tons of structural steel for about 2,000,000 sq. ft of enclosed space, making the structural steel weight approximately 19 lb per sq. ft. The tower sits atop a five-story podium and five levels of underground parking.

A sail-like crown using 900 tons of steel and an architectural spire us-ing 124 tons top the building, which is expected to achieve LEED Silver certification. It is the first high-rise building in downtown L.A. to be constructed without a flat roof.

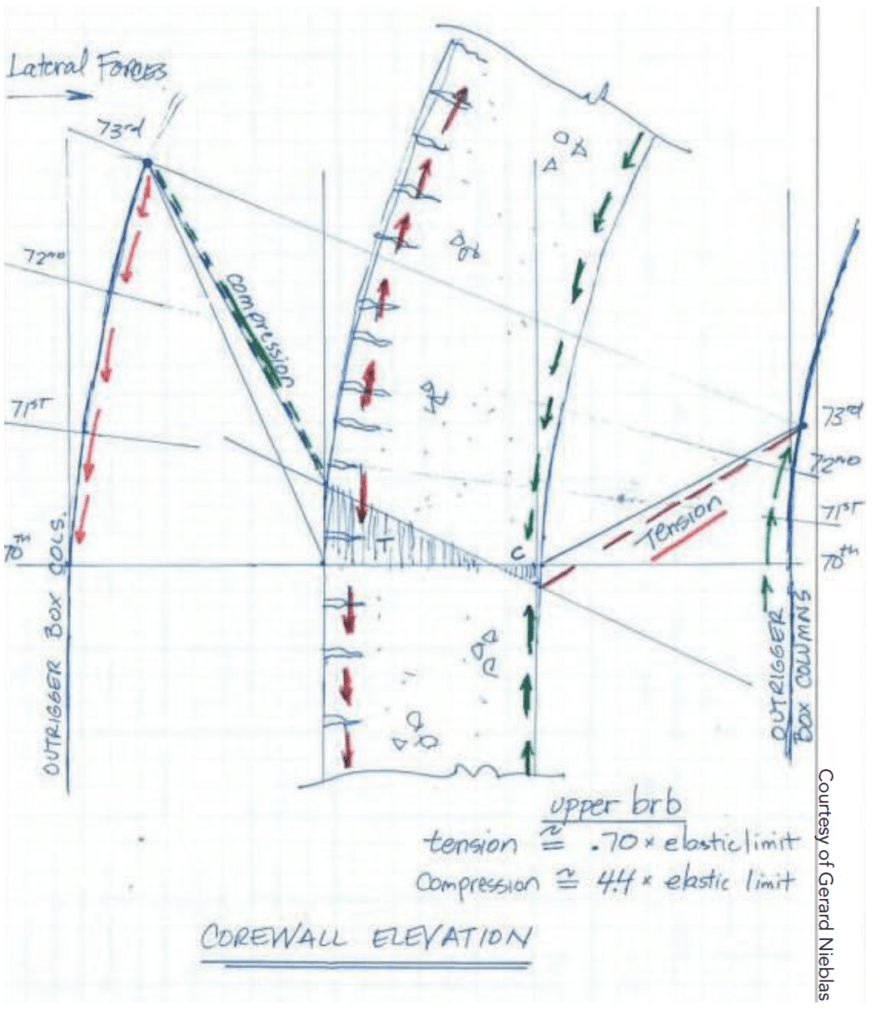

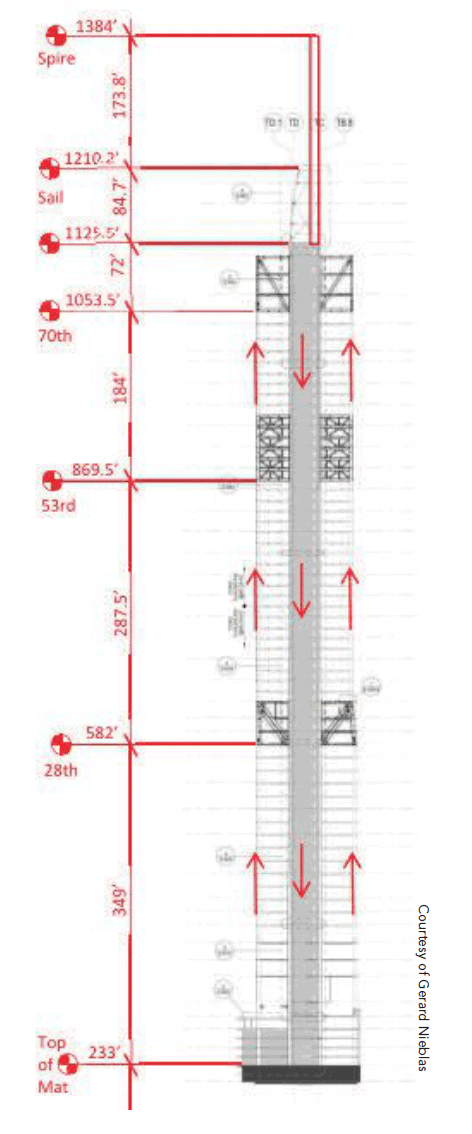

Because the structure is so tall and slender, it was necessary to introduce steel outriggers to resist the wind and seismic over-turning and to provide rigidity for wind and seismic drifts. In the transverse direction the core wall is 30 ft wide and approximately 895 ft tall. As the concrete creeps and shrinks, the steel BRBs (buckling restrained braces) are pulled downward in tension, pushing down on the exterior building columns over time.

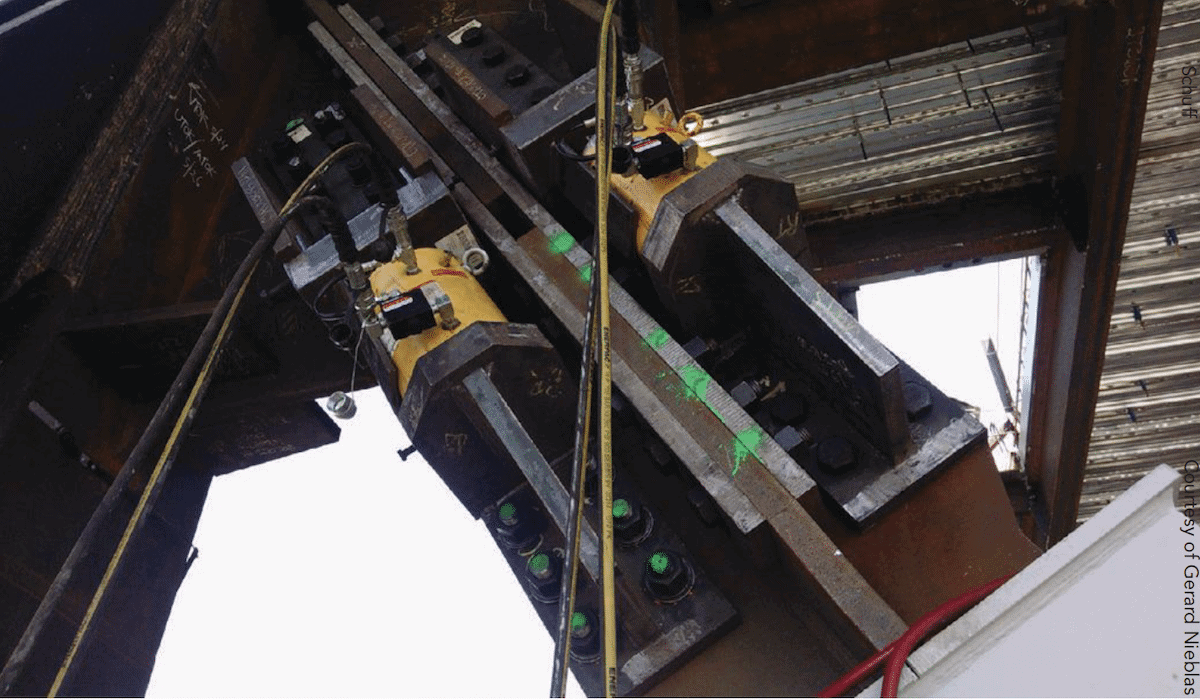

The tower employs 40 2,200-kip BRB outriggers at the low-er levels (28 to 31), 120 800-kip BRB outriggers in the middle levels (52 to 58) and 10 2,200-kip BRB outriggers in the upper levels (71 to 73). Each BRB weighs roughly 19.5 tons and they are positioned four per joint, resulting in a capacity of 8,800 kips at 10 different points. The BRBs, which act as seismic fuses in the event of an earthquake, at the lower levels are all 42 ft long and span from the exterior wall into the core wall. The bot-tom connection for each consists of a 7½-in.-diameter pinned clevis into 2¾-in.-thick gusset plates, and the top connections are 1½-in. A490 bolts through 1½-in.-thick splice plates over 2-in. gusset/core plates.

The building also has two three-story-tall belt trusses around the perimeter at the lower and upper outrigger levels. These belt trusses increase torsional stiffness in the structure, distribute vertical loads more uniformly around the perimeter of the structure and add redundancy to the structural system.

Electro-slag welding was incorporated for AWS D1.8 demand-critical welds at the lower BRB levels, something that had never been done as a field application in high-rise steel construction. This required many rounds of procedure qualification records and demonstrations to prove that the application would work. All lower belt truss chords and braces (W14 members), as well as the gusset plates for BRB connections to the core wall embeds, were welded using this process. These gusset plates were over 12 ft tall and 2½ in. thick and were each welded only a few hours after setting up the joint.

Early in the design process, the team investigated using conventional brace elements as part of the outrigger system. How-ever, this proved to be too heavy-handed a solution. Conventional wide-flange braces would have been too massive in terms of thickness to withstand the buckling effect in compression—much larger than necessary when controlled by tension forces. In addition, conventional braces for the out-rigger system would have resulted in larger connections, as the braces would have been sized based on compression but the connections would have been sized based on tension, resulting in more unpredictable jamb forces on the outrigger columns.

BRBs were selected so that brace areas could be sized based on tension in-stead of compression, which resulted in less demanding connections to the core wall and outrigger columns and smaller, more predictable jamb forces to the outrigger columns. The BRBs serve as a fuse for the vertical wind and seismic jamb forces and provide a consistent, predictable load to the foundation.

The upper outrigger BRBs are attached near the top of the core wall and are therefore the most sensitive to the differential movement between the shrinkage, creep and elastic shortening of the core wall and the elastic shortening of the structural steel box columns. An extensive study conducted to approximate the anticipated total creep and shrinkage in the core wall also included a yearlong creep and shrinkage testing program of the proposed concrete mix with a shrinkage-reducing admixture. A core wall construction sequence analysis was required to evaluate the force transfers based on a construction schedule provided by the contractor.

Pre-Compression

Since the concrete core wall is so thick, it takes an extremely long time for all the drying shrinkage to occur. For example, at the bottom third of the structure the core wall is 48 in. thick. It will take approximately 54 years to achieve 75% of the drying shrinkage for a wall of this thickness.

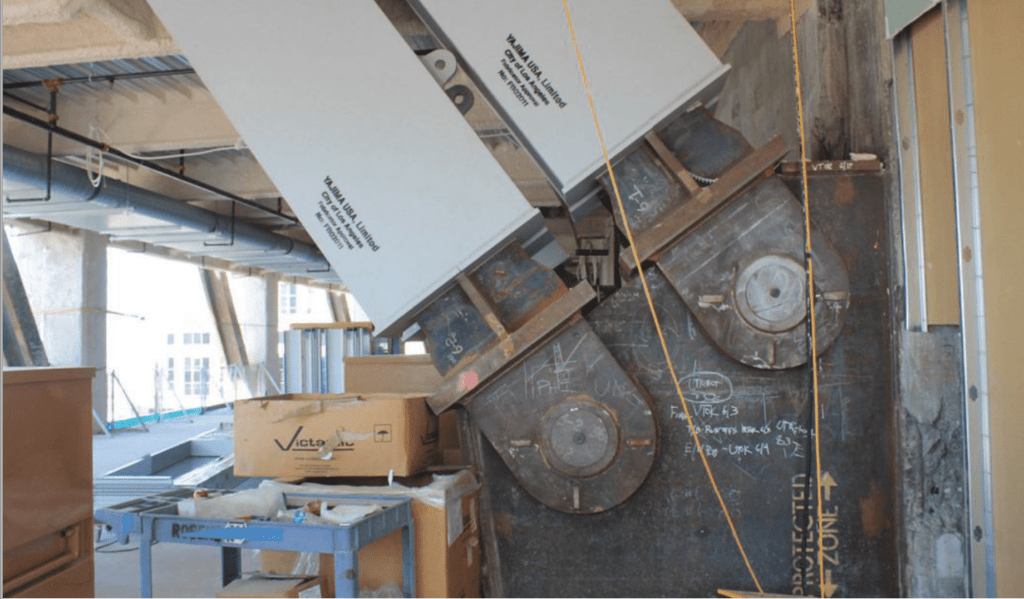

To mitigate the large tensile force transfer in the braces due to the core wall shortening, the team jacked each of the upper BRBs with a pre-compression force of 1,000 kips. Four flat jacks were placed at the top of each BRB at the 73rd floor. The jacking force was measured by hydraulic pressure in the lines and by measuring the compression strains in each of the braces. Alternate sides of the building were jacked in ¼-in. increments over the course of a day. Once approximately ½ in. of compressive strain was placed into each BRB, they were locked off with bolted connections.

The primary reason for this compression jacking was to protect the structure from permanent tensile deformation in a 50-year wind event or short-term moderate seismic event. The reason the precompression is so effective is because the tensile/compression strains on the BRBs are not equal. For the maximum considered earthquake (MCE) the compression strains are on average six times more than the tensile strains. The BRB strains are approximately 50% of yield strain for the 50-year wind event, and pre-compressing these braces eliminates permanent deformations after 50 years of creep and shrinkage.

After jacking 500 tons of compression into the 10 braces, the 10 exterior build-ing columns went into tension as the brac-es pushed upward on the perimeter of the structure. The 73rd floor at the perimeter of the structure rose vertically ½ in., with each floor below rising slightly less to the middle outrigger level, and the perimeter columns were in tension to the middle out-rigger level—exactly as planned.

Owner/Developer: Hanjin Group, Seoul, South Korea

Architect: AC Martin Partners, Los Angeles

General Contractor: Turner Construction Co., Los Angeles

Structural Engineer: Brandow and Johnston, Inc., Los Angeles

Performance-Based Design Consultant: Thornton Tomasetti, Los Angeles

Steel Team: Fabricator and Erector Schuff Steel, San Diego

Detailer: BDS VirCon, Brisbane, Australia