Reconstruction National Award – Wells Street Bridge, Chicago IL.

The Wells Street Bridge is the longest double deck, double leaf, bascule bridge built over the Chicago River, and only one of two remaining bascule bridges in the city of Chicago that carries both automobile and transit (Chicago Transit Authority elevated trains) on two levels.

Recent in-depth inspection and analysis of the 1922 built bridge revealed that substantial structural rehabilitation was required. As the steel bridge carries an average daily traffic of approximately 12,000 vehicles and serves nearly 4,500 pedestrians a day on the lower level and a two major transit lines carrying 70,000 riders per day on the upper level, the crucial crossing had to be rehabilitated with minimal impact to its users.

In the initial design plan, CTA would only allow weekend shutdowns, which only provided for partial replacement of select members. To accomplish this partial replacement the rail operations would have needed to be suspended for I 5 long weekends throughout the year, a situation that was deemed unacceptable. Instead, it was determined that the replacement of the steel truss “river arm” structure and framing would take place during two nine day shutdowns of upper level train traffic (two weekends and one work week).

The main span of the bridge is 345 ft long and 72 ft wide. Dual open web trusses, as main load carrying members, support both levels of framing. Both levels of framing were entirely replaced along with major rehabilitation to the mechanical and electrical components of the steel bridge. Bridge houses and bridge pits, including counterweight boxes, received select repairs. Due to the steel bridge’s historic status, most elements such as the railings, bridge houses and major structural components were replaced in kind to preserve the historic look.

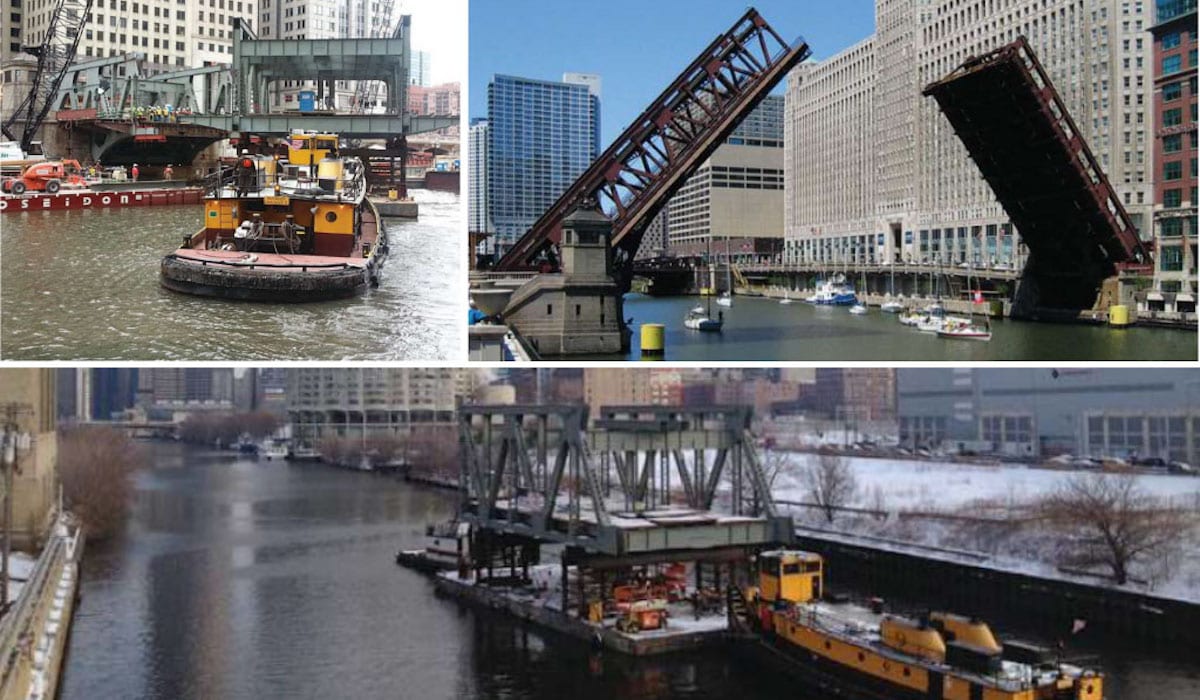

The bridge was rehabilitated one leaf at a time, providing temporary shoring under the counterweight box for the leaf under construction so train traffic could be maintained. Vehicle and pedestrian traffic was safely detoured to other local streets and bridges over the river, and working on only one leaf at a time allowed one leaf to remain operable to accommodate river traffic.

The first shutdown took place in March 2013 and another in April 2013. During each line cut, transit service over the structure was halted on a Friday evening and resumed again by rush hour on the second Monday. As CTA was planning to perform loop track repairs around the same time frame as the Wells Bridge rehabilitation and these repairs would have required additional weekend shutdowns. The two projects were combined and resulted in minimal impact to users as well as a $500,000 savings for the city.

Steel construction staging was perhaps the most complex part of the work and the key to the success of the project. In addition to the limited closures for CTA trains, the Coast Guard required that one leaf be operational at all times between March and October, because the bridge was located over a river in the heart of the city, nearby streets were not available for the staging of the material, and the project relied heavily on marine equipment for staging. Before the project was bid, an early procurement contract was awarded for the river arm structural steel fabrication. The fabricator stored the trusses and assisted the contractor in assembly of the truss/floor beam river arm that was eventually barged to the site.

Achieving bridge balance was another challenge. In order to proceed with work on the north leaf, the south leaf first needed to be operational, which required the latter to be balanced in the interim condition. To balance the bridge for operation, concrete jersey barriers were lashed to the deck toward the nose of the span. The north leaf counterweight was then shored and the construction sequence was repeated for the north leaf.

The Wells Street Bridge project demonstrates that in situ rehabilitation of moveable structures nearing their useful life can be a viable alternative to replacement. Full scale replacement of moveable bridges can be a long process often requiring realignment, property acquisition and displacement of people and businesses. The rehabilitation of the Wells Street structure was performed with minimal disruption to local businesses in a congested urban site.

Owner

Chicago Department of Transportation, Chicago

Designer

AECOM, Chicago

Contractor

Walsh Construction and II in One (JV), Chicago

Steel Fabricator

Munster Steel Company, Inc., Hammond, Ind.

Steel Detailer

DBM Vircon Services Ltd., New Westminster, B.C., Canada

First published in Modern Steel Construction

THE COUNTRY’S BEST STEEL BRIDGES have been honored in this year’s Prize Bridge Awards competition. Conducted every two years by the National Steel Bridge Alliance (NSBA), the program honors outstanding and innovative steel bridges constructed in the U.S. The awards are presented in several categories: major span, long span, medium span, short span, movable span, reconstructed, special purpose, accelerated bridge construction and sustainability. This year’s 16 winners, divided into Prize and Merit winners, range from a mammoth marquee Mississippi River crossing to the country’s first steel extradosed bridge. Winning bridge projects were selected based on innovation, aesthetics and design and engineering solutions, by a jury of five bridge professionals.

This year’s competition included a variety of steel bridge structure types and construction methods. All structures were required to have opened to traffic between May 1, 2013 and September 30, 2015.

The competition originated in 1928, with the Sixth Street Bridge in Pittsburgh taking first place, and over the years more than 300 bridges have won in a variety of categories. Between 1928 and 1977, the Prize Bridge Competition was held annually, and since then has been held every other year, with the winners being announced at NSBA’s World Steel Bridge Symposium.

2016 Prize Bridge Awards Jury

David Spires, P.E. Senior Engineering Manager with WSP Parsons Brinckerhoff Michael Culmo, P.E. Vice President of Transportation and Structures with CME Engineering Brian Kozy, P.E., Ph.D. Structural Engineering Division Team Leader with FHWASteve Jacobi, P.E. State Bridge Engineer for the Oklahoma Department of TransportationCarmen Swanwick, S.E. Chief Structural Engineer for the Utah Department of Transportation