Sellwood Bridge – Portland, OR.

In a city known for its bridges, Portland, Oregon’s Sellwood Bridge over the Willamette River stands out amongst the rest for its elegant, flowing lines and low profile. It is also the city’s first steel deck arch structure and currently the only structure crossing the Willamette River that meets modern seismic requirements.

The original Sellwood Bridge opened in 1925 and became the busiest two lane bridge in the state. In 2005, it received a National Bridge Inventory sufficiency rating of 2 out of a possible 100. This low rating was attributed to critical issues such as deterioration of the approach structures and extensive cracking in the concrete girders, which was caused by a nearby hillside that was slowly sliding into the river, thus exerting pressure on the west end of the bridge.

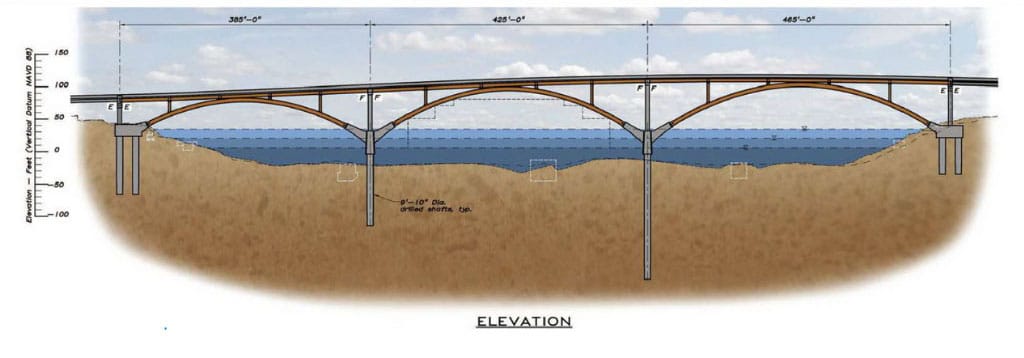

Using 5,000 tons of structural steel, the new 1,976ft long replacement bridge with 1,275 ft comprising the steel deck arch features three arch spans that support the 63ft wide to 90ft wide deck of the main river spans. The bridge carries two 12ft wide vehicular lanes, two 6.5ft wide bike lanes/emergency shoulders and two 12ft wide shared use sidewalks, and will also accommodate future streetcar service. The project included the replacement bridge, modernization of the Highway 43 interchange and stabilization of the hillside located west of the bridge and interchange.

As the profile for the new bridge ascended from west to east, the arch spans could not be in balance geometrically, which affected the differential thrust across the interior piers. The three arches have a rise to span ratio that varies from 1:7.7 (0.13) to 1:6.4 (0.16). The arch framing was scaled to trend with the profile, allowing the necessary balance at the piers. This same geometry for a deck arch resulted in rather shallow arches shallower than structurally optimum for a deck arch. Bending moments from dead load for fixed arches would have dominated the arch size, creating a heavier arch profile. Through an innovative use of advanced ultra high molecular weight (UHM”W) plastic hinges, engineer T.Y. Lin designed the arch ribs to be pinned during construction, allowing rotation of the rib springing. Connections were designed to allow grouting and bolting of the springing at completion of the bridge for the desired continuity needed for live and seismic loadings.

Another challenge was how to replace a major transportation route with minimal traffic disruption. The original plan was to build the replacement bridge in two halves, using the existing span for traffic while the southern half of the new bridge was built first. Once the southern half was completed, traffic would shift onto it, allowing demolition of the old bridge and construction to begin on the northern half of the new bridge. However, this plan had its drawbacks, including the need for extensive staging to keep traffic moving and increased construction time and costs. As such, an alternative solution was developed. Once temporary steel piers were erected north of the existing bridge piers, the entire 1,100ft long steel deck truss of the old bridge, comprising four continuous deck truss spans, was slid over on rails to a detour alignment using hydraulic jacks. The horizontal distance of the move was 66 ft at the west end and 3 3 ft at the east end. Temporary approach spans at both ends of the truss were also constructed. This solution enabled the replacement bridge to be built in one phase on the original bridge footprint. Benefits included eliminating the need for staged construction; reducing the number of arch ribs from four to two; freeing up the existing alignment for work crews; enhancing public safety by removing traffic from the construction zone; and reducing bridge closure time to only six days.

Multnomah County also saved up to a year in construction time and as much as $10 million in project costs with some help from steel fabricator, Thompson Metal Fab. The company proposed piece-by-piece stick erection for the steel deck arch, with arch ribs placed on shoring towers rather than the float in system originally considered for arch erection. Each rib span contained two bolted field splices to match the optimum weights chosen by general contractor Sundt Construction for fabrication and erection. This resulted in three segments per span, with segment lengths of up to 148 ft and weights of up to 146 tons each. Steel was transported to the site on barges and placed with cranes operating from work bridges and these barges.

Owner

Multnomah County, Ore.

General Contractor

Sundt Construction, LLC

Structural Engineer

T.Y. Lin International

Steel Team

Detailer

Candraft Detailing, Inc., New Westminster, B.C., Canada

First published in Modern Steel Construction

AMERICA’S BEST STEEL BRIDGES have been honored in this year’s Prize Bridge Awards competition. Conducted every two years by the National Steel Bridge Alliance (NSBA), the program honors outstanding and innovative steel bridges constructed in the U.S. The awards are presented in several categories: major span, long span, medium span, short span, movable bridge, reconstructed, technological advancement, integrated project delivery, special purpose, accelerated bridge construction and sustainability. This year’s 16 winners, divided into Prize and Merit winners, include a first-of-its-kind tub girder solution in Ohio, a remote crossing in the frigid far north of Alaska and a modest double counterweight design in a coastal Maine town. Winning bridge projects were selected based on innovation, aesthetics and design and engineering solutions by a jury of five bridge professionals.

This year’s competition included a variety of bridge structure types and construction methods. All structures were required to have opened to traffic between May 1, 2015 and September 30, 2017. The competition originated in 1928, with the Sixth Street Bridge in Pittsburgh taking first place, and over the years more than 300 bridges have won in a variety of categories.

Between 1928 and 1977, the Prize Bridge Competition was held annually, and since then has been held every other year, with the winners being announced at NSBA’s World Steel Bridge Symposium.

Judges

Amber Blanchard, PE, Minnesota Department of Transportation

Michael Culmo, PE, CME Engineering

Tony Hunley, PE, PhD, Stantec

Frank Russo, PE, PhD, Michael Baker International

Dominique Shannon, PE, Kansas Department of Transportation