Quite often, environmental sustainability and the energy and resource intensive construction industry fail to work in unison. It is well-established that the construction industry consumes a huge volume of raw materials and natural resources—according to the World Green Building Council, the construction industry generates an estimated 37% of the world’s carbon emissions.

There is a multitude of economic and social imperatives for investing, developing, designing and constructing sustainable buildings, infrastructure and other assets. Incorporating sustainable principles in construction projects can reduce construction and operating costs, lower risks in ongoing asset management, and enhance quality of life for future generations.

However, engineering and construction leaders face competing pressures as they try to transition to more sustainable construction practices well before an asset is operational. Balancing competing objectives such as controlling costs and maintaining productivity and efficiency, while reducing energy consumption can be near impossible; just consider how much energy-intensive heavy plant and machinery is necessary on a large-scale construction site.

Construction Modeling and detailing of everything from steel, concrete, timber and vendor items can play an important role in bolstering the sustainability credentials of construction projects. Pre-construction planning, modeling and detailing can assist in minimising waste, reducing rework and the consumption of these raw materials.

Why is Sustainability Important?

Finding new and innovative construction processes and techniques that balance the needs of major projects with the need for sustainable development will ensure a more prosperous future. While sustainability might feel like it has been an industry buzz-word for years, this is not without its reasons.

Sustainable operating principles and practises are essential for the survival and continued success of humanity. One of the United Nations Sustainable Development Goals (SDG) is Goal 9: Industry, Innovation and Infrastructure. This focuses on the importance of improving the energy consumption curve of the industrial sector, from construction to operations, all the way through to reclamation at the asset’s end of life.

According to the World Green Building Council, 75% of annual global greenhouse emissions are from the built environment, with buildings on their own accounting for 37%. Between 40 and 50% of resources extracted for global materials are used for housing, construction and infrastructure, and building materials account for half the solid waste generated every year worldwide. And with 75% of the infrastructure needed globally by 2050 yet to be built, there is huge scope for improvement.

Creating a more sustainable sector is about so much more than limiting damage to the natural environment; sustainability is important in the way that all organisations operate in terms of their workforce, processes, budgets and schedules. A more sustainable approach to large scale projects can assist to keep costs down, minimise waste and ensure that these important global projects can continue to provide the world with essential resources for generations to come.

How Quality Pre-Construction Planning and Detailing Can Improve Sustainability

Pre-construction planning, modeling and detailing with an experienced team can improve sustainability outcomes for construction companies and projects.

Minimised Waste

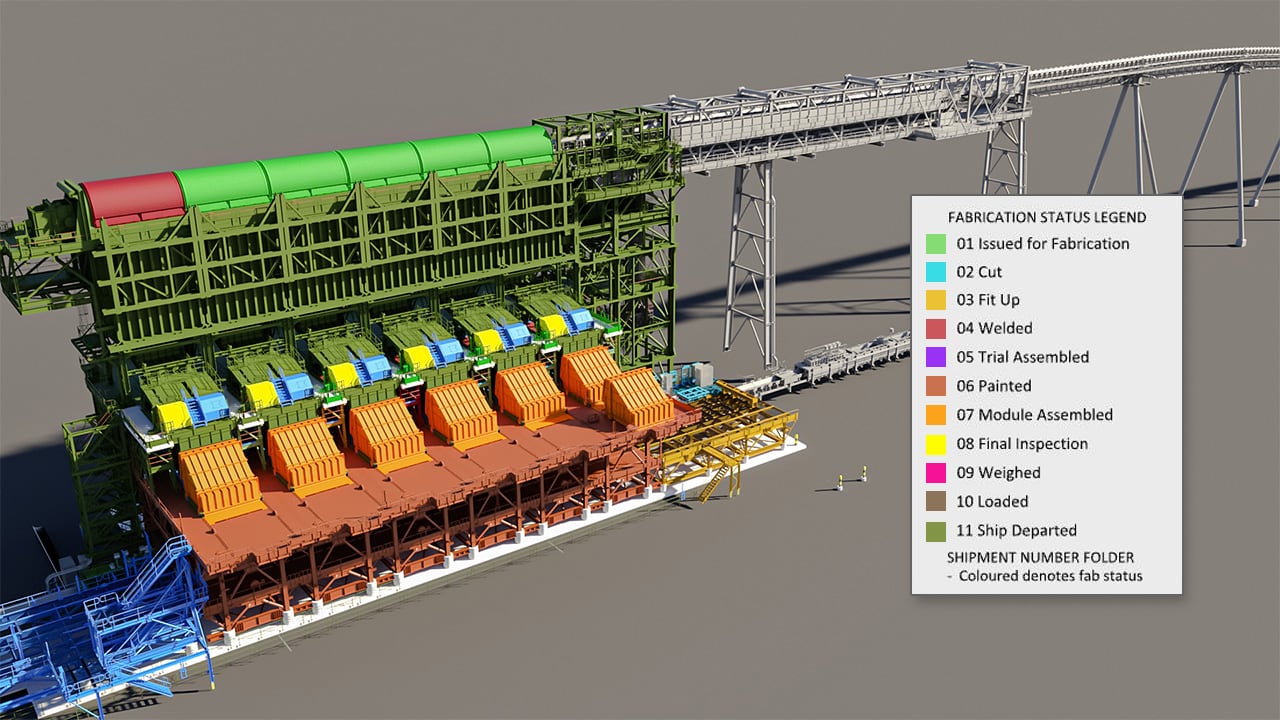

Quality Construction modeling and detailing play a key role in reducing the waste produced by a construction project. By using millimetre-perfect models, materials procurement is highly accurate—materials need not be wasted. Experienced Construction Modelers are able to integrate data from all design disciplines and streamline team communication to resolve poor design documentation and reduce clashes, so fabricators produce and deliver accurate steel—the first time.

Reduced Rework

Rework costs construction companies time, money, and resources. It also has a negative influence on the sustainability of a project, contributing to additional energy and materials usage. Employing the services of an experienced Construction Modeler ensures that projects run more smoothly without the need to fix costly errors on site such as the cutting and grinding of steel and concrete as well as welding on site, accurate modeling interfacing of all disciplines always greatly reduces the likelihood of work needing to be redone.

Reduced Project Timeframes

An integrated structural steelwork detailing model improves efficiencies across the project lifecycle through parallel workflows and reduced duplication, shortening a project’s construction schedule by up to 12%. With reduced construction timeframes, energy consumption and carbon emissions are also reduced—heavy plant and equipment is not in operation on-site for such prolonged periods.

Decreased Travel

Travelling to remote sites generates an enormous carbon footprint. When this is undertaken by multiple personnel and heavy equipment, it severely impacts the sustainability of a project. Accurate Construction Modeling and Detailing decreases the need for travel—both for personnel and materials—with a large volume of steel accurately pre-fabricated before site delivery.

Streamlined Lifecycle Planning

A key part of sustainable construction is creating buildings and infrastructure that fulfil their purpose and can continue to do so for the long term. This means getting the design right the first time. Designs should take the entire life cycle of an asset into consideration, including the potential of a design model being used for maintenance management in the future.