Upon the November 2021 passing of the $1.2 Trillion Infrastructure Bill, The New York Times featured an article about the many recent large scale projects across the country that massively overran their original cost and schedule estimates.

These delays and budget blow-outs are all too common in the United States. According to a report by the American Road and Transport Builders Association, 16 states have announced project delays valued at nearly $5.01 billion.

The result: delayed benefits to the public and an inflated price tag that taxpayers ultimately bear.

With a troubled track history combined with record high material pricing, how can governments, contractors and infrastructure project teams help mitigate these high-risk, challenging projects? How can project teams speed up steel design and construction and make the most of this generational investment in our infrastructure?

The Solution: Design Integration and 3D Modeling

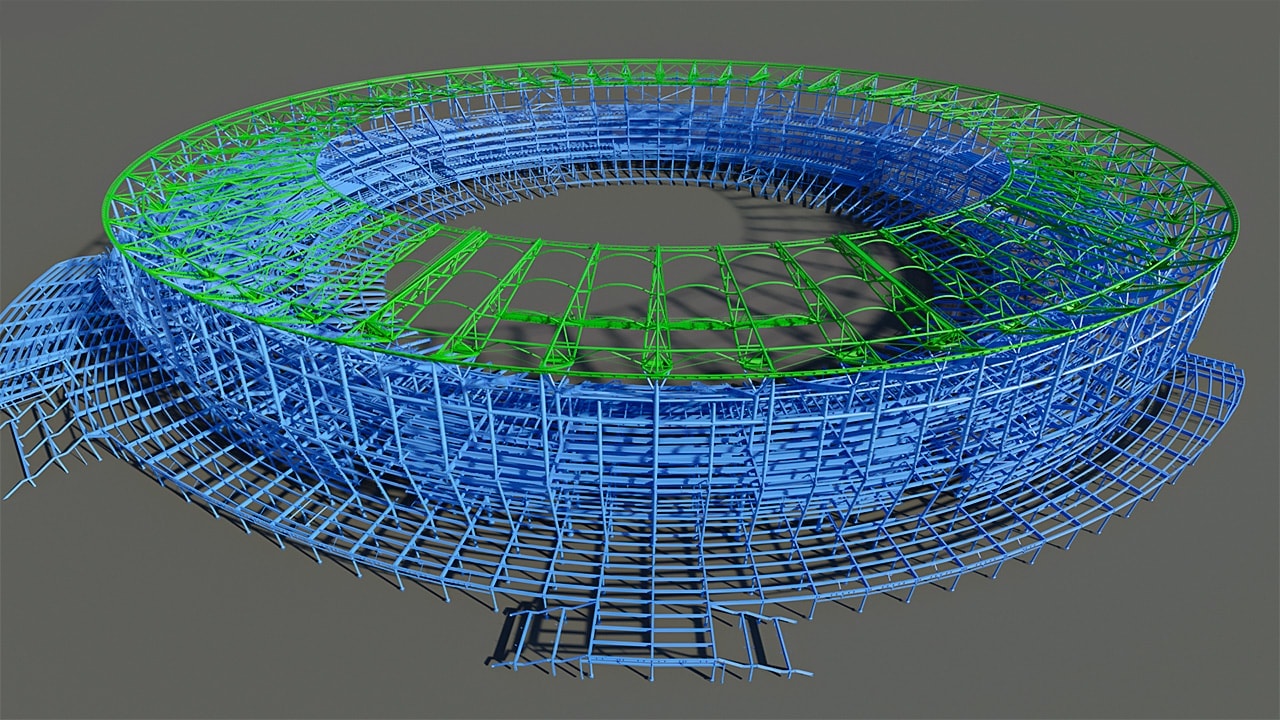

One solution that is rapidly gaining traction is Design Integration and 3D modelling—implemented as early as possible in a project’s life cycle.

Design Integration helps bridge the gap between design and construction. Collaborative early engagement methodologies like Design Assist, Design Integration or Integrated Project Delivery help ensure scheduling certainty in a relatively short span of time. While engineering designs focus on life safety requirements and develop novel approaches while creating analysis models, Design Integration analyzes project intricacies to resolve issues like accessibility, constructability and erectability—reducing costs, slashing project timeframes and ensuring scheduling certainty all while producing a fabrication ready model with detailed, easy to understand data.

Eradicate Value Engineering

Design Integration and 3D modeling help eradicate the value engineering that is so typical of Design-Bid-Build projects. It helps keep projects on schedule and on budget, without the aesthetic, size or functionality compromises that are a necessary evil of the value engineering process.

Confirm Constructability

Constructability assessments in a 3D model can step through every aspect of framing plans to ensure that steelwork can be easily fabricated and erected. This provides accurate costs and scheduling certainty. All steel members can be reviewed for profile, location and elevation and connections can be reviewed for clearance and accessibility checks. Unique erection schemes involving modularization or panelization can also be considered.

Detect Clashes

Rework and replacement of structural steelwork can be incredibly expensive and cause severe project delays. Design Integration in combination with multi-discipline 3D model coordination, incorporating all construction services, delivers fully integrated clash detection capabilities to resolve delays and rework. Interactive development streamlines the design process by checking fit-up, and resolving design discrepancies and intent before the final phase of the geometry lockdown.

By investing in Design Integration, undertaken by a partner, the enhanced constructability of a project pays for itself many times over. The partner then verifies all elements of a steel structure, confirming constructability and avoiding clashes, to help eradicate rework and project delays. Ultimately, this helps speed up both the design and construction phases of steel intensive projects.

By Christopher Pfeiff, Global General Manager Commercial