Robert F. Kennedy Bridge – Manhattan Approach Ramps

When building a new bridge proved too costly, steel’s ability to be retrofitted provided the economical solution for the RFK Bridge Manhattan approach ramps. Aside from localized deterioration, the steel superstructure of these approach ramps was in good structural condition but did not meet modern seismic requirements. Because of the bridge’s importance as an evacuation route, the steel superstructure was retrofitted to include a seismic isolation system, thus extending the useful life of the bridge dramatically.

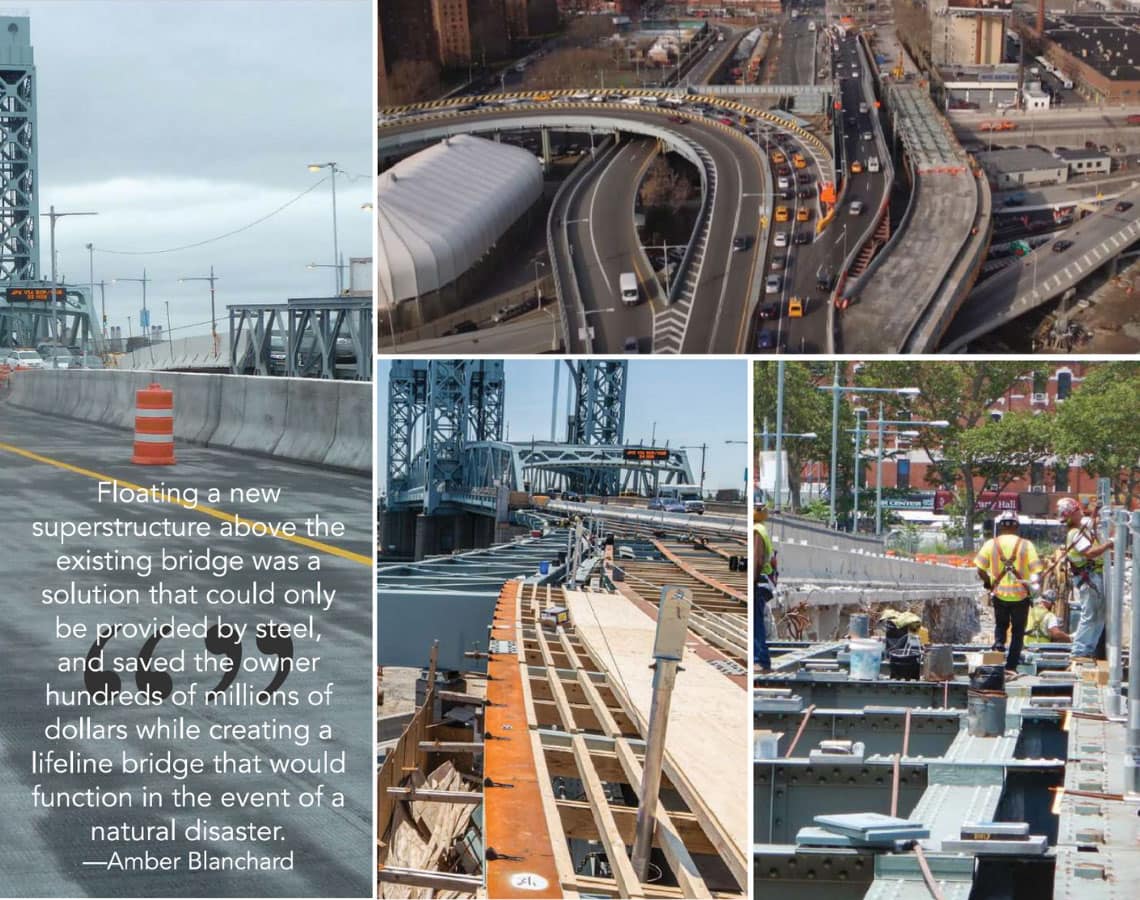

Prior to this project, no major rehabilitation had been performed on the Manhattan approach ramps to the RFK Bridge (officially known as the Robert F. Kennedy Harlem River Lift Bridge) since its original construction in 1936. Due the effects of chronic deterioration, primarily at the locations of leaking expansion joints, a comprehensive rehabilitation effort of the steel portion of the structure was required. A number of unique and innovative methods were necessary to successfully complete this project within the congested urban environment all while maintaining traffic on these critical ramps, which carry in excess of 85,000 vehicles per day.

The original structure consisted of concrete “cellular” spans near grade transitioning to steel rigid-frame spans for the elevated portions. While the concrete spans had significantly deteriorated and were in need of replacement, the steel spans were in relatively good condition (aside from localized deterioration near the expansion joints) making them a good candidate for rehabilitation. The steel structure consists of a nonredundant, two-girder system with typical span lengths of 60 ft framing directly into steel rigid-frame pier bents. The original structure does not use expansion joints; expansion and contraction is instead accommodated by flexure of the steel columns (which are oriented for weak axis bending in the longitudinal direction of the bridge).

Due to this structure’s importance as an emergency evacuation route, it is classified as a “critical” structure for purposes of seismic analysis and must be able to resist a 2,500 year return period event with minimal damage. “Extreme event” loads of this magnitude were not explicitly considered during the original design of the structure. As expected, the results of initial analyses indicated that numerous structural elements had inadequate capacity to resist these loads. These initial analyses showed that the existing steel rigid-frame pier columns benefited from the fact that they are rather flexible under lateral loading, resulting in relatively low seismic demands. However, there were certain vulnerable regions, specifically the column-to-girder and column-to-floor-beam connections, that were overstressed during the modeled seismic event. Due to details that are relatively common for structures of this era (built up members with riveted construction, etc.), strengthening of these vulnerable locations was found to be problematic and cost prohibitive (if not altogether unfeasible) due to tight access and the labor intensive nature of the work. Since the existing concrete deck was slated to be replaced due to the advanced level of deterioration present, a “floating deck” isolation system was developed to reduce seismic demands by isolating the new steel deck and floor system from the existing steel rigid-frame substructure below. The isolation scheme that was developed resulted in a reduction in seismic demands such that only a handful of strengthening retrofits were required all of which were located at regions that were relatively easy to access.

Unlike most isolation systems which typically use conventional lead core or elastomeric isolation bearings for this very flexible structure it was necessary to develop a hybrid system using both sliding bearings (typical PTFE stainless steel interfaces) and elastomeric bearings. In this design, the sliding bearings carry all vertical loads and dissipate energy through friction, while only a small number of isolation bearings are needed, solely to provide the required restoring force. At the service load level, the friction developed at the sliding bearings resists the lateral design forces of wind, live load braking and live load centrifugal force (where applicable on the curved section of the on ramp). The details of the floating deck seismic isolation system also resulted in the removal of the majority of the expansion joints, thereby reducing the major source of deterioration (namely chloride laden water infiltrating the steel) and creating a more maintenance free structure.

The original replacement cost was estimated by some to be as high as $200 million, and such a project would have been more disruptive to traffic and the local community in this highly congested area of Manhattan. But the rehabilitation solution developed by engineer Modjeski and Masters cost roughly $70 million, of which only a small percentage went to the cost of isolation bearings and installation of the additional seismic retrofits.

Owner

Triborough Bridge and Tunnel Authority

General Contractor

Defoe Corporation

Structural Engineer

Modjeski and Masters, Inc.

Detailer

Candraft Detailing, Inc., New Westminster, B.C., Canada

First published in Modern Steel Construction

AMERICA’S BEST STEEL BRIDGES have been honored in this year’s Prize Bridge Awards competition. Conducted every two years by the National Steel Bridge Alliance (NSBA), the program honors outstanding and innovative steel bridges constructed in the U.S. The awards are presented in several categories: major span, long span, medium span, short span, movable bridge, reconstructed, technological advancement, integrated project delivery, special purpose, accelerated bridge construction and sustainability. This year’s 16 winners, divided into Prize and Merit winners, include a first-of-its-kind tub girder solution in Ohio, a remote crossing in the frigid far north of Alaska and a modest double counterweight design in a coastal Maine town. Winning bridge projects were selected based on innovation, aesthetics and design and engineering solutions by a jury of five bridge professionals.

This year’s competition included a variety of bridge structure types and construction methods. All structures were required to have opened to traffic between May 1, 2015 and September 30, 2017. The competition originated in 1928, with the Sixth Street Bridge in Pittsburgh taking first place, and over the years more than 300 bridges have won in a variety of categories.

Between 1928 and 1977, the Prize Bridge Competition was held annually, and since then has been held every other year, with the winners being announced at NSBA’s World Steel Bridge Symposium.

Judges

Amber Blanchard, PE, Minnesota Department of Transportation

Michael Culmo, PE, CME Engineering

Tony Hunley, PE, PhD, Stantec

Frank Russo, PE, PhD, Michael Baker International

Dominique Shannon, PE, Kansas Department of Transportation