Plant Vogtle stands as a four-unit nuclear power facility in Georgia, United States. With Unit 3 already operational and Unit 4 currently undergoing final construction and testing stages, this expansion project reflects a steadfast commitment to shaping the state’s future in clean energy.

The new units are set to supply reliable, emissions-free power to approximately 500,000 homes and businesses, contributing to sustainable energy solutions.

Throughout the project’s inception, an impressive quantity of over 680,000 cubic yards of concrete has been laid for the new units. Vogtle Units 3 and 4 represent the first implementation of the AP1000 Generation III+ reactor in the United States. The AP1000 reactor boasts evolutionary enhancements over existing reactors, incorporating advanced safety mechanisms.

DBM Vircon Scope of Work:

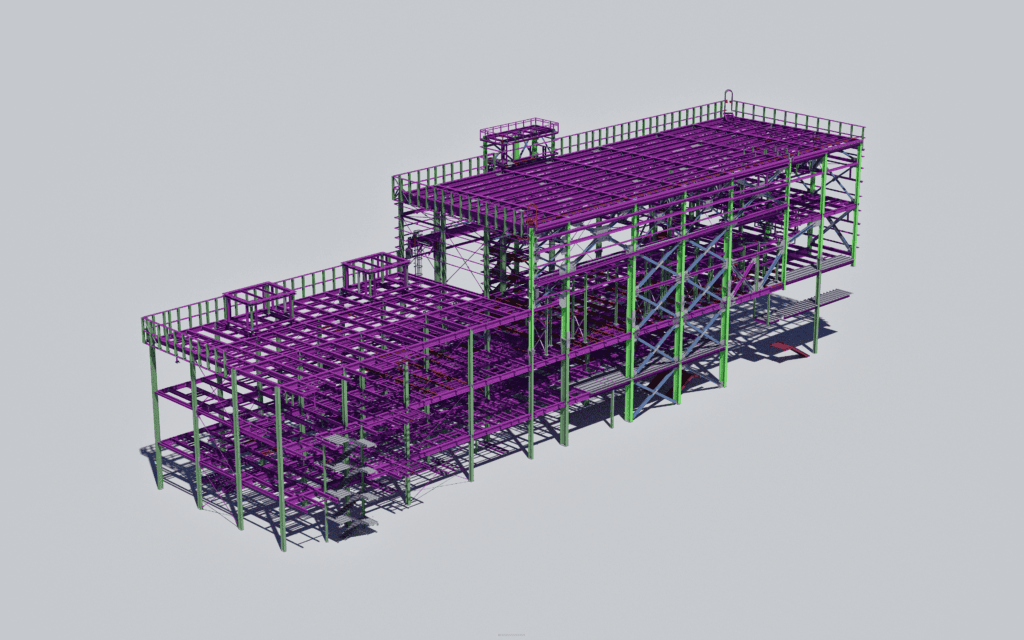

DBM Vircon were engaged by SteelFab, Inc., for the Vogtle Nuclear Plant Project to provide shop detailing services, 2D drawings, and associated 3D models for the Annex Buildings along with miscellaneous components such as elevator shafts, handrails, and stairs.

The Annex Buildings, each weighing approximately 1100 tons per unit, required the assembly of about 8300 components per building.

Initially, the objective was to detail a single building, with plans to duplicate the drawings for the remaining three structures, thus optimizing both time and cost. The initial strategy focused on efficiency through a unified Tekla model for all four identical buildings. However, the project’s dynamic nature introduced complexities with distinct design revisions that were specific to individual structures. As a result, a secondary model was developed to accommodate these evolving intricacies.

The project required the management of two models to encompass the four buildings, with one model serving two buildings.

DBM Vircon and SteelFab’s connection designer worked closely together to coordinate design details and revisions.

Project Challenges/Highlights:

One of the primary challenges was to pivot from our initial strategy, which aimed to utilize a single Tekla model for all four identical buildings. However, as the project progressed, unique design revisions were applicable only to 1 or 2 buildings. DBM Vircon addressed this challenge by creating a second model to accommodate revisions on different buildings. To ensure smooth operations, two managers were present at the fabrication shop, quickly handling any urgent issues. Additionally, a dedicated night-shift team carefully edited drawings to demonstrate their strong dedication to the project.