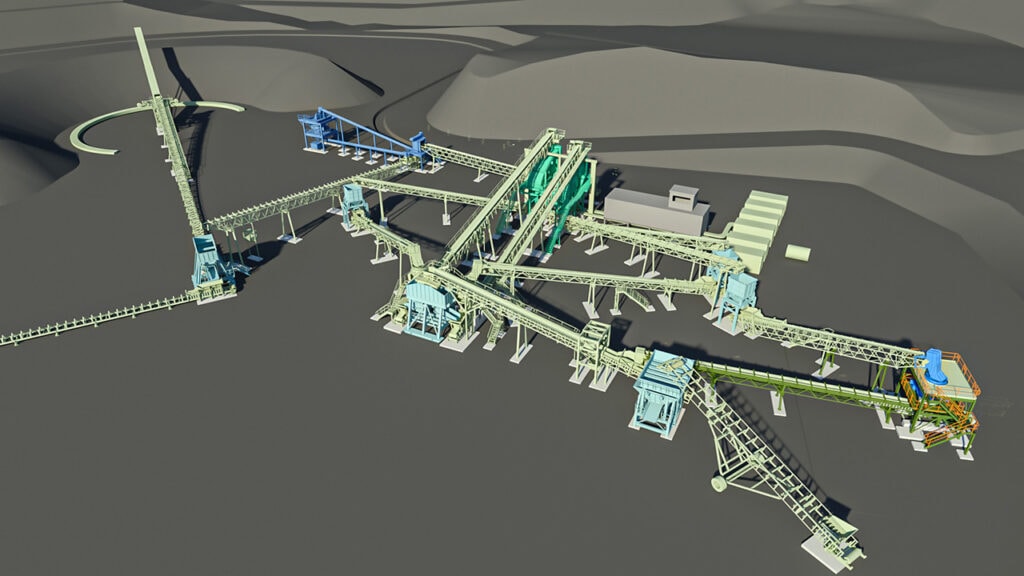

Voyager II Quarry Primary Crushing Facility & Brickworks

Voyager II Quarry Primary Crushing Facility & Brickworks

BGC’s new Voyager II quarry replaces the nearby ageing facilities. The product produced is crushed granite in 7 aggregate sizes from dust to 20mm. The primary crushing facility is...

VIEW PROJECT DETAILS