Risk management is critical in the delivery of major mining, oil and gas projects. It ensures that projects can be completed safely, on time, within budget and with the best quality outcomes.

Collaborating with experienced construction modelers can help de-risk both construction and maintenance activities, streamline processes and ensure that planning for key deliverables can be commenced as early as possible. In an industry plagued by consistent challenges such as skills deficiencies, material shortages and unpredictable global geopolitical challenges, de-risking is essential to success.

The Risks Facing Mining, Oil and Gas Construction Projects

If we look at the way industry has evolved over the last 20 years, one of the most significant changes has been the structure of engineering teams—the key role of Designer has become increasingly rare. Traditionally, the Designer sat between the Engineer and the Detailer, and was tasked with expressing the engineering intent. Without this critical piece of the puzzle, there is a reduced capacity to help bridge the gap between concept, engineering and fabrication.

This challenge is compounded by continued pressure on engineering teams to hand over drawings or models on ever increasingly complex infrastructure and machinery as quickly as possible in order to accelerate fabrication and commence construction. The adage of ‘time is money’ is constricting engineering timeframes. Changing roles and compressed project schedules necessitate collaboration between engineers, project owners and detailers.

These changing roles have fundamentally altered what a traditional detailer does, so much so that the term ‘detailer’ has nearly become antiquated. There has been an industry push toward something that better captures the scope detailers now undertake giving rise to ‘construction modelers’.

Engineering Skills Shortages

Australia is staring down the barrel of an engineering skills shortage. According to research from Engineers Australia, the national engineering vacancy rate skyrocketed by as much as 50 per cent in 2021 compared to 12 months prior. The most highly sought after are civil engineers, followed by industrial, production and mechanical engineers—all of which play a vital role in the mining, oil and gas industries.

In the US, the Bureau of Labor Statistics predicts that 140,000 new engineering jobs will be created by 2026 in the US alone. Again, the most in-demand engineering disciplines are civil, mechanical and industrial.

This incredible global demand for professional engineers has been exacerbated by COVID-19 and its various impacts, such as prolonged border closures that curtailed skilled international migration. The geopolitical landscape (including the Ukraine war, conflict between Taiwan and China, and international trade disputes) is also impacting skilled migration. This has left a gap that cannot be filled by university graduates.

As a result, the nature of engineering deliverables is changing. Often, construction modelers are responsible for translating the engineering outputs (which are less detailed, less thorough and less complete than they would have been historically) to ensure the fabricator has a clear, concise and complete package of fabrication information to work from.

Shortened Timeline and Compressed Schedules

Scheduling is a common issue for major industrial projects and poses a significant risk to stakeholders. There is strong market demand for important commodities with very little notice. This demand means that clients in the mining, oil and gas industries need project deliverables urgently—often projects have to get underway rapidly due to a number of pressures.

This situation is being exacerbated by the current climate, with severe shortages in construction materials resulting in lead times that are much longer then normal. As a result, materials must be ordered even earlier than usual to ensure on-time project delivery. In addition, the materials ordered must be accurate; they must be the correct size and length, and quantities must be perfect. The lead time on replacement material is huge, disrupting project schedules enormously.

And yet, clients in the mining, oil and gas industries are obligated to stretch their budgets further than ever before, in line with increased accountability to shareholders. This leaves engineering houses that are already facing skills shortages in an increasingly difficult position, and projects at a greater risk than ever before.

How High-Quality Construction Modeling and Detailing Can Help Overcome The Risks

While there is no one magic bullet that can eliminate these industry-wide liabilities altogether, construction modeling is uniquely placed to help alleviate risks within the mining, oil and gas industries.

Bridging the Skills Gap

Early engagement of construction modelers to produce accurate models during a design assist phase can help in managing the risks posed by skill and material shortages, bridging the gap between engineering and fabrication.

Experienced construction modelers work collaboratively in both the design and fabrication environments, helping identify issues before they become problems. Leveraging the latest integrated software solutions and processes, construction modelers can apply a collaborative approach that delivers cost and schedule certainty, and improves site readiness.

By utilising construction modeling, the number of personnel required for a project can be reduced, helping control costs and improve communication. A construction modeler can assume a design assist role, taking on the dual responsibilities of designer and detailer, and work with the engineer in a shared model rather than from traditional drawings.

Working with a construction modeler speeds up projects and helps to manage shortened timelines by streamlining design processes and avoiding design document double-handling along the way. Construction modeling can assist a project to move more quickly from the conceptual phase to fabrication drawings. Working in the detail environment allows for earlier release of long lead items from engineering, meaning that fabrication and construction can commence earlier.

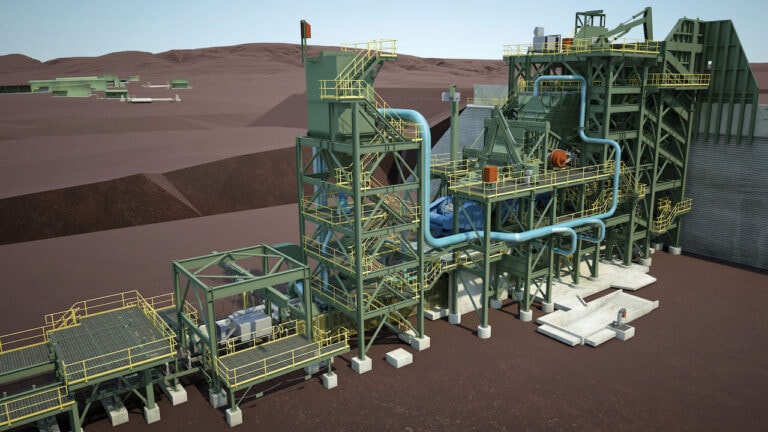

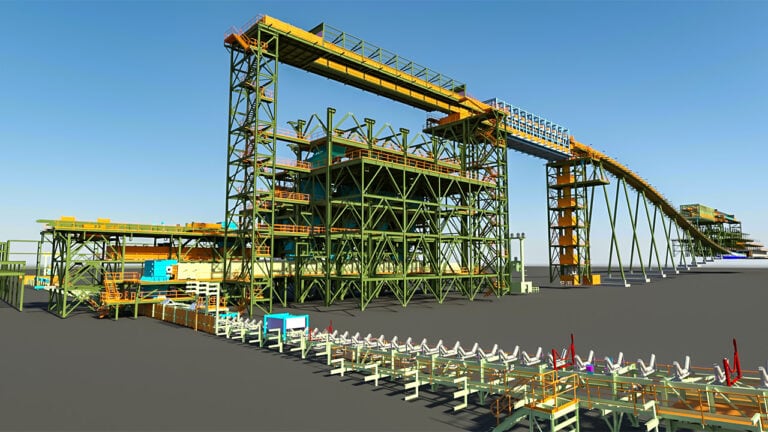

Whether it’s helping fill in the gaps in design for large mining projects, providing traditional detailing services for material handling infrastructure (like crushing and screening facilities, conveyor systems and transfer stations), or supporting engineering reviews for complex industrial equipment (like stackers and reclaimers), construction modelers can help de-risk a project.

Avoiding Material Shortages

Detailed models can be used for procurement and ordering of materials, helping to manage the added risk of supply shortages that can delay project commencement and completion. The early involvement of construction modelers reduces this risk by producing accurate and highly detailed models in the beginning stages of a project, which can be used for material procurement and planning.

Improving Quality and Safety Outcomes

Construction modeling allows for the creation of millimetre-perfect accurate models which can be used for a wide range of purposes throughout the lifespan of a project – from conception and logistics planning to final implementation. This model becomes the ‘single source of truth’ on a project, allowing an engineer to control final deliverable requirements (including models, drawings, reports and metadata) to ensure they meet client requirements with less risk of having to go back and re-capture information later. Some of the many advantages offered by working in a three-dimensional environment from the outset include the ability to plan for modularization, the possibility to fabricate offshore without the loss of accuracy or quality, and the detailed management of project metadata.

Additionally, detailed models can be used for visualisation of 4D sequences, allowing project personnel to make decisions early and identify any risks. These include health and safety concerns and procedural risks, such as clashes in machinery and scaffolding. The use of detailed models means these problems can be identified and de-risked months ahead of schedule, improving outcomes for the project and avoiding any impacts to schedules and budgets.

Providing Construction Modeling and Detailing Services to Global

Whether it’s a large-scale LNG plant, complex mining machinery with thousands of moving parts, or the most intricate of services that cannot clash, a construction modeling and detailing partner that has tangible in-depth project delivery experience is critical. An experienced construction modeling and detailing team is able to take a step back and identify the commonalities between seemingly different projects. They can then apply previous project experience and lessons learnt to produce informed strategies and advice based on tangible project delivery experience.

With a strong track record of improving site readiness, delivering cost certainty and reducing risk, their approach improves outcomes for mining, oil and gas projects around the world.